Automatic waterers provide a consistent and clean water supply, reducing the risk of contamination and dehydration in chickens. Manual waterers require frequent refilling and cleaning, which can be time-consuming and may lead to inconsistent hydration. Choosing an automatic waterer improves flock health by ensuring chickens have continuous access to fresh water.

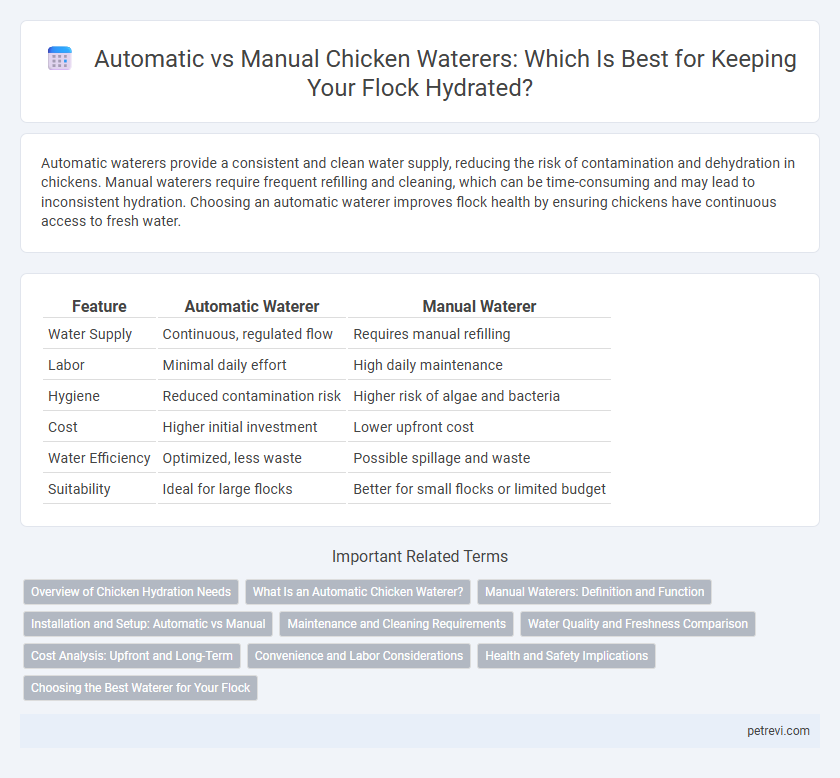

Table of Comparison

| Feature | Automatic Waterer | Manual Waterer |

|---|---|---|

| Water Supply | Continuous, regulated flow | Requires manual refilling |

| Labor | Minimal daily effort | High daily maintenance |

| Hygiene | Reduced contamination risk | Higher risk of algae and bacteria |

| Cost | Higher initial investment | Lower upfront cost |

| Water Efficiency | Optimized, less waste | Possible spillage and waste |

| Suitability | Ideal for large flocks | Better for small flocks or limited budget |

Overview of Chicken Hydration Needs

Chickens require consistent access to clean, fresh water to maintain optimal hydration, supporting digestion, egg production, and overall health. Automatic waterers provide a steady supply by regulating flow and reducing contamination risk, while manual waterers require frequent refilling and monitoring to prevent dehydration. Proper hydration systems are essential to prevent stress and promote growth in poultry management.

What Is an Automatic Chicken Waterer?

An automatic chicken waterer is a device designed to provide a continuous, clean supply of water to poultry without manual refilling. It typically uses gravity or a connected water source with a float valve to maintain a consistent water level, reducing the risk of contamination and dehydration. This system improves flock hydration by ensuring chickens have constant access to fresh water, especially beneficial for larger or free-range flocks.

Manual Waterers: Definition and Function

Manual waterers for chicken hydration are simple devices that require farmers to fill and refill water containers by hand, ensuring direct control over water cleanliness and availability. These waterers typically consist of troughs or cups connected to a reservoir, allowing chickens to drink as needed while preventing excess spillage. Manual waterers are cost-effective and straightforward to maintain but demand regular attention to keep water fresh and prevent dehydration risks.

Installation and Setup: Automatic vs Manual

Automatic waterers require a more complex installation involving plumbing connections and water pressure adjustments to ensure consistent flow, making setup time longer compared to manual waterers. Manual waterers are straightforward to install, often needing only a clean container and regular refilling, making them ideal for smaller flocks or temporary setups. Proper installation of automatic systems minimizes water waste and contamination, while manual systems rely heavily on frequent human intervention to maintain hydration.

Maintenance and Cleaning Requirements

Automatic waterers significantly reduce daily maintenance by providing a consistent water supply with minimal monitoring, requiring occasional cleaning to prevent algae and mineral buildup. Manual waterers demand frequent refilling and thorough cleaning to ensure water remains fresh, increasing labor intensity and the risk of dehydration if neglected. Proper maintenance of both systems is crucial for preventing bacterial growth and promoting optimal hydration and health in chickens.

Water Quality and Freshness Comparison

Automatic waterers ensure consistent water quality by providing a continuous supply of fresh, filtered water, reducing bacterial growth and contamination risks compared to manual waterers. Manual waterers often face challenges in maintaining freshness as water can stagnate between refills, increasing exposure to dirt and pathogens. Investing in automatic systems enhances chicken health by minimizing waterborne diseases linked to poor hydration hygiene.

Cost Analysis: Upfront and Long-Term

Automatic waterers for chicken hydration involve higher upfront costs due to installation and equipment, yet they reduce labor expenses and water waste over time, resulting in lower long-term operational costs. Manual waterers have minimal initial investment but require continuous manual refilling, increasing labor costs and risk of inconsistent water availability that can affect flock health. Evaluating cost-efficiency depends on flock size and management style, with automatic systems proving more economical for large-scale operations.

Convenience and Labor Considerations

Automatic waterers provide consistent, clean water supply with minimal effort, significantly reducing daily labor and preventing dehydration risks in chickens. Manual waterers demand frequent refilling and cleaning, increasing labor time and the chance of water contamination. For large flocks, automatic systems enhance convenience and ensure reliable hydration, improving overall poultry health and productivity.

Health and Safety Implications

Automatic waterers for chicken hydration reduce the risk of contamination and bacterial growth by providing a constant supply of fresh, clean water, which promotes better flock health and lowers the chances of waterborne diseases. Manual waterers require frequent monitoring and cleaning to prevent stagnation and contamination, increasing the potential for pathogens that can compromise chicken immune systems. Proper hydration with safe water sources supports optimal digestion and egg production while minimizing stress-related health issues in poultry.

Choosing the Best Waterer for Your Flock

Automatic waterers provide consistent, clean water supply, reducing the risk of contamination and saving time for large flocks. Manual waterers offer control and simplicity, ideal for small flocks or areas with limited water access but require frequent refilling and maintenance. Evaluating flock size, water quality, and labor availability ensures selecting the most effective hydration system for chicken health and productivity.

Automatic Waterer vs Manual Waterer for Chicken Hydration Infographic

petrevi.com

petrevi.com