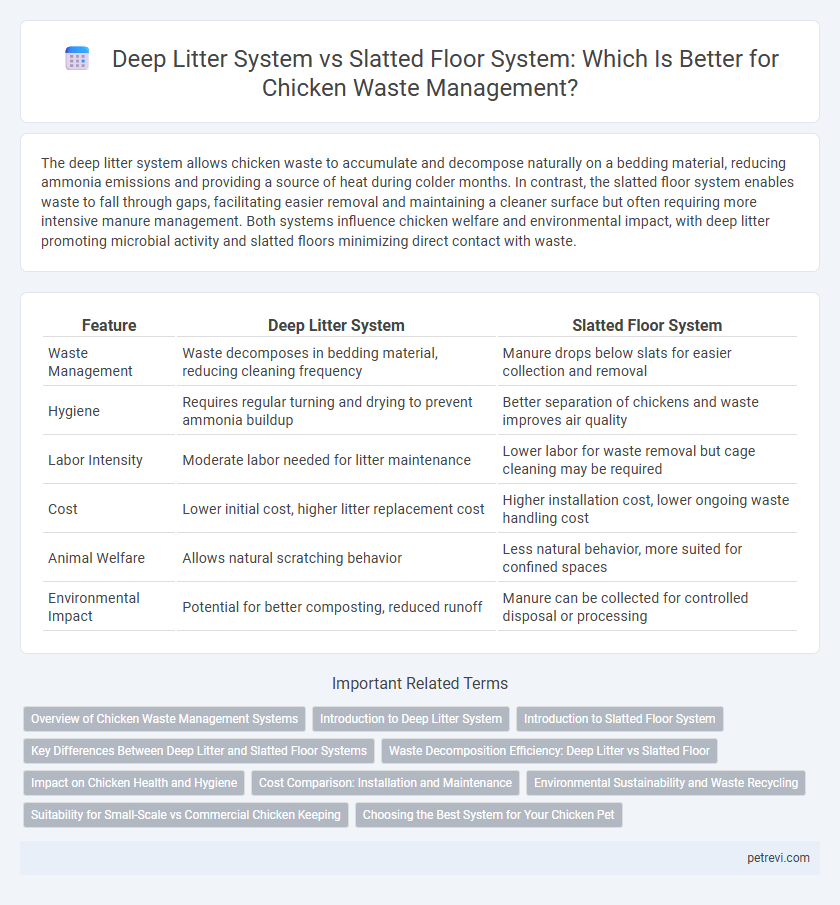

The deep litter system allows chicken waste to accumulate and decompose naturally on a bedding material, reducing ammonia emissions and providing a source of heat during colder months. In contrast, the slatted floor system enables waste to fall through gaps, facilitating easier removal and maintaining a cleaner surface but often requiring more intensive manure management. Both systems influence chicken welfare and environmental impact, with deep litter promoting microbial activity and slatted floors minimizing direct contact with waste.

Table of Comparison

| Feature | Deep Litter System | Slatted Floor System |

|---|---|---|

| Waste Management | Waste decomposes in bedding material, reducing cleaning frequency | Manure drops below slats for easier collection and removal |

| Hygiene | Requires regular turning and drying to prevent ammonia buildup | Better separation of chickens and waste improves air quality |

| Labor Intensity | Moderate labor needed for litter maintenance | Lower labor for waste removal but cage cleaning may be required |

| Cost | Lower initial cost, higher litter replacement cost | Higher installation cost, lower ongoing waste handling cost |

| Animal Welfare | Allows natural scratching behavior | Less natural behavior, more suited for confined spaces |

| Environmental Impact | Potential for better composting, reduced runoff | Manure can be collected for controlled disposal or processing |

Overview of Chicken Waste Management Systems

Chicken waste management systems primarily consist of the deep litter system and the slatted floor system, each designed to optimize hygiene and environmental control in poultry housing. The deep litter system uses a bedding material that absorbs moisture and facilitates composting of manure directly on the floor, promoting natural decomposition and reducing odor. In contrast, the slatted floor system allows manure to fall through gaps into a collection area, enabling easier removal and reducing direct chicken contact with waste, thereby enhancing sanitation and minimizing ammonia buildup.

Introduction to Deep Litter System

The Deep Litter System involves layering organic bedding materials such as wood shavings or straw on the poultry house floor, allowing chicken waste to decompose naturally within the litter. This method promotes microbial activity that breaks down manure, reducing odor and facilitating nutrient recycling for agricultural use. Compared to the Slatted Floor System, Deep Litter requires less infrastructure investment and supports better moisture control within the coop environment.

Introduction to Slatted Floor System

The slatted floor system in chicken waste management features elevated platforms with spaced slats allowing manure to fall directly into collection pits below, promoting cleaner living conditions and reducing pathogen exposure. This design improves ventilation and minimizes moisture buildup compared to deep litter systems, enhancing overall flock health. Efficient waste removal in slatted floor systems supports sustainable poultry farming by simplifying manure management and reducing labor costs.

Key Differences Between Deep Litter and Slatted Floor Systems

The deep litter system for chicken waste management involves bedding materials like straw or wood shavings that absorb moisture and promote microbial decomposition, resulting in manageable compostable waste. The slatted floor system separates waste by allowing droppings to fall through gaps, minimizing direct contact and facilitating easier collection but often requires regular cleaning beneath the slats. Key differences include waste handling methods, hygiene levels, and labor intensity, with deep litter promoting natural breakdown and slatted floors enabling quicker waste removal.

Waste Decomposition Efficiency: Deep Litter vs Slatted Floor

The deep litter system promotes higher waste decomposition efficiency by utilizing microbial activity within organic bedding materials, facilitating natural breakdown of chicken waste and reducing ammonia levels. In contrast, the slatted floor system allows droppings to fall through gaps, minimizing direct contact but slowing microbial degradation due to limited organic matter accumulation. Consequently, the deep litter method enhances nutrient recycling and reduces pathogen buildup, while the slatted floor system requires more frequent cleaning to manage waste effectively.

Impact on Chicken Health and Hygiene

The deep litter system promotes natural behaviors and provides insulation, which can improve chicken comfort but may increase ammonia levels if not managed properly, potentially affecting respiratory health. The slatted floor system facilitates better waste drainage and reduces direct contact with feces, significantly decreasing the risk of bacterial infections and improving overall hygiene. Both systems require regular maintenance to balance cleanliness and environmental conditions critical for optimal chicken health.

Cost Comparison: Installation and Maintenance

The deep litter system typically incurs lower installation costs as it requires simple bedding materials like straw or wood shavings spread over a solid floor, eliminating the need for complex drainage infrastructure. Maintenance expenses are generally reduced due to natural composting of waste within the litter, minimizing labor and disposal costs compared to the slatted floor system. Conversely, the slatted floor system demands higher upfront investment for durable materials and structural support, with increased ongoing costs for regular cleaning and manure removal to prevent accumulation beneath the slats.

Environmental Sustainability and Waste Recycling

The deep litter system enhances environmental sustainability by promoting natural composting of chicken waste, reducing ammonia emissions and enabling on-site nutrient recycling for soil enrichment. In contrast, the slatted floor system facilitates easier waste removal and management but often requires external treatment, which may increase environmental impact. Effective waste recycling in the deep litter system reduces landfill reliance and supports circular agriculture, making it a greener option for poultry manure management.

Suitability for Small-Scale vs Commercial Chicken Keeping

The deep litter system is highly suitable for small-scale chicken keeping due to its low-cost setup and natural waste decomposition, promoting healthier manure for use as fertilizer. The slatted floor system, favored in commercial operations, enables efficient waste removal and better hygiene management, reducing disease risks in large flocks. Small-scale farmers benefit from the deep litter's simplicity, while commercial producers gain productivity and sanitation advantages from slatted floors.

Choosing the Best System for Your Chicken Pet

The deep litter system promotes natural decomposition of chicken waste, enhancing soil fertility and reducing odor through microbial activity, making it ideal for backyard chicken keepers seeking low-maintenance waste management. In contrast, the slatted floor system offers superior hygiene by allowing droppings to fall through gaps into collection trays, minimizing direct contact and easing waste removal in commercial or more controlled environments. Selecting the best system depends on factors like flock size, space availability, and desired labor intensity, with deep litter suitable for smaller, sustainable setups and slatted floors preferred in intensive, large-scale poultry operations.

Deep litter system vs Slatted floor system for Chicken Waste Management Infographic

petrevi.com

petrevi.com