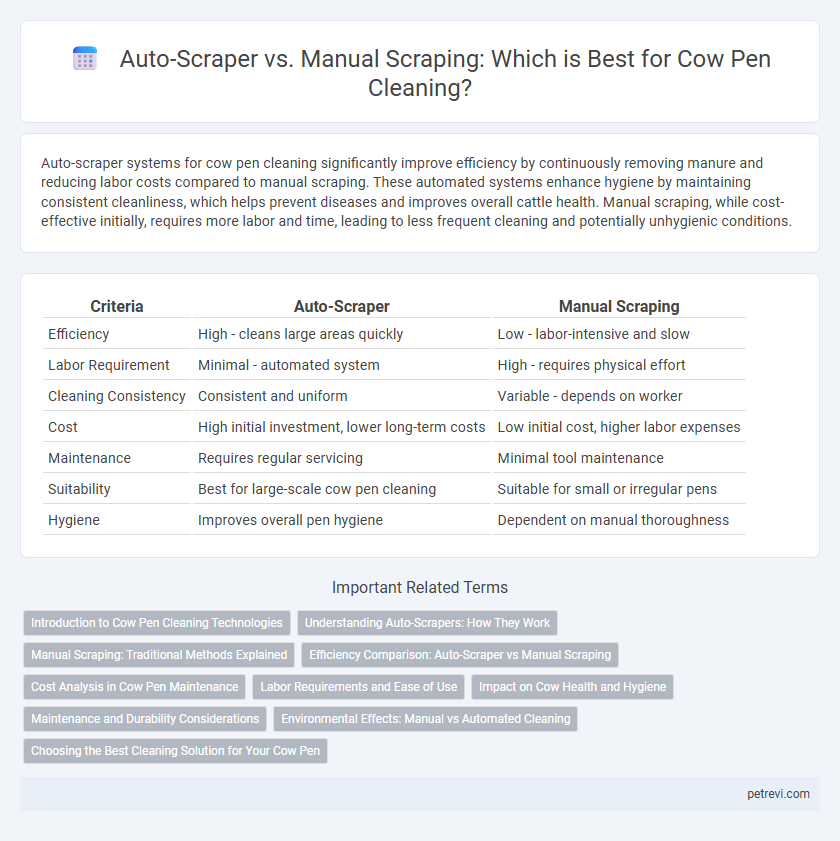

Auto-scraper systems for cow pen cleaning significantly improve efficiency by continuously removing manure and reducing labor costs compared to manual scraping. These automated systems enhance hygiene by maintaining consistent cleanliness, which helps prevent diseases and improves overall cattle health. Manual scraping, while cost-effective initially, requires more labor and time, leading to less frequent cleaning and potentially unhygienic conditions.

Table of Comparison

| Criteria | Auto-Scraper | Manual Scraping |

|---|---|---|

| Efficiency | High - cleans large areas quickly | Low - labor-intensive and slow |

| Labor Requirement | Minimal - automated system | High - requires physical effort |

| Cleaning Consistency | Consistent and uniform | Variable - depends on worker |

| Cost | High initial investment, lower long-term costs | Low initial cost, higher labor expenses |

| Maintenance | Requires regular servicing | Minimal tool maintenance |

| Suitability | Best for large-scale cow pen cleaning | Suitable for small or irregular pens |

| Hygiene | Improves overall pen hygiene | Dependent on manual thoroughness |

Introduction to Cow Pen Cleaning Technologies

Cow pen cleaning technologies have evolved from manual scraping using handheld tools to automated systems that ensure consistent hygiene and reduce labor costs. Auto-scrapers use mechanized blades or conveyor belts to remove manure efficiently, minimizing the risk of disease and improving animal welfare. Manual scraping relies on human effort, offering flexibility but limiting scalability and timeliness in maintaining pen cleanliness.

Understanding Auto-Scrapers: How They Work

Auto-scrapers for cow pen cleaning utilize motorized blades and sensors to efficiently remove manure and debris, reducing labor intensity and improving hygiene. These devices operate on programmable schedules and can adapt to different pen sizes, ensuring consistent cleanliness without constant human intervention. Their automated mechanism enhances overall animal welfare by maintaining a dry, sanitary environment that minimizes disease risks in dairy farming.

Manual Scraping: Traditional Methods Explained

Manual scraping for cow pen cleaning involves physically removing manure and debris by hand or with basic tools, ensuring thoroughness and immediate inspection of the pen's condition. This traditional method allows for targeted cleaning in hard-to-reach areas, reducing the risk of animal health issues caused by accumulated waste. Although labor-intensive, manual scraping remains effective for maintaining hygiene and preventing the spread of bacteria and parasites in cow pens.

Efficiency Comparison: Auto-Scraper vs Manual Scraping

Auto-scraper systems for cow pen cleaning significantly outperform manual scraping by increasing efficiency through consistent and continuous operation, reducing labor costs and time spent per cleaning cycle. These automated devices utilize sensors and programmed patterns to ensure thorough waste removal, maintaining optimal hygiene levels that are challenging to achieve manually. Manual scraping, while flexible and low-cost upfront, often results in inconsistent cleanliness and higher physical labor demands, making auto-scraping a superior choice for large-scale dairy operations seeking productivity and sanitation excellence.

Cost Analysis in Cow Pen Maintenance

Auto-scraper systems for cow pen cleaning significantly reduce labor costs by automating manure removal, leading to lower operational expenses compared to manual scraping. Initial investment for auto-scraper installation ranges from $10,000 to $50,000, but long-term savings on labor and improved hygiene reduce veterinary and maintenance costs. Manual scraping incurs higher recurring labor costs and inconsistent cleanliness, potentially increasing disease risk and affecting overall productivity.

Labor Requirements and Ease of Use

Auto-scraper systems for cow pen cleaning significantly reduce labor requirements by automating waste removal, minimizing the need for manual intervention and lowering worker fatigue. Manual scraping demands continuous physical effort, specialized skill, and a higher labor workforce, increasing operational costs and time. Auto-scrapers are designed for ease of use, enabling quick setup and consistent performance, which enhances productivity compared to the variability and complexity of manual cleaning methods.

Impact on Cow Health and Hygiene

Auto-scraper technology in cow pen cleaning significantly enhances hygiene by consistently removing waste, reducing bacterial buildup, and minimizing ammonia levels that can cause respiratory issues in cows. Manual scraping, while allowing targeted cleaning, often leads to inconsistent waste removal, increasing the risk of pathogen growth and foot diseases. Consistent cleanliness achieved through auto-scraping directly contributes to improved cow health, reducing mastitis incidence and promoting better overall animal welfare.

Maintenance and Durability Considerations

Auto-scraper systems for cow pen cleaning provide enhanced maintenance efficiency by reducing manual labor and minimizing wear on equipment due to consistent, controlled scraping cycles. Manual scraping, while more flexible for adjusting to varied pen conditions, often results in uneven wear and requires frequent maintenance checks, impacting overall durability. Investing in auto-scraper technology improves long-term durability through optimized cleaning patterns and less mechanical stress on scraper components.

Environmental Effects: Manual vs Automated Cleaning

Automated cow pen cleaning systems significantly reduce water consumption and minimize chemical runoff compared to manual scraping, lowering environmental pollution. Manual scraping often leads to inconsistent waste removal, increasing contamination risks in soil and nearby water sources due to leftover organic matter and residues. Advanced auto-scraper technologies improve manure management efficiency, promoting sustainable farming practices by reducing greenhouse gas emissions and nutrient leaching.

Choosing the Best Cleaning Solution for Your Cow Pen

Auto-scraper systems optimize cow pen cleaning by reducing labor time and maintaining consistent sanitation, leading to healthier livestock and increased milk production. Manual scraping requires significant physical effort and can result in uneven cleanliness, potentially causing hoof diseases and reducing cow comfort. Investing in an automated scraper offers long-term cost savings and improved herd welfare, making it the preferred choice for efficient cow pen maintenance.

Auto-scraper vs Manual scraping for Cow pen cleaning Infographic

petrevi.com

petrevi.com