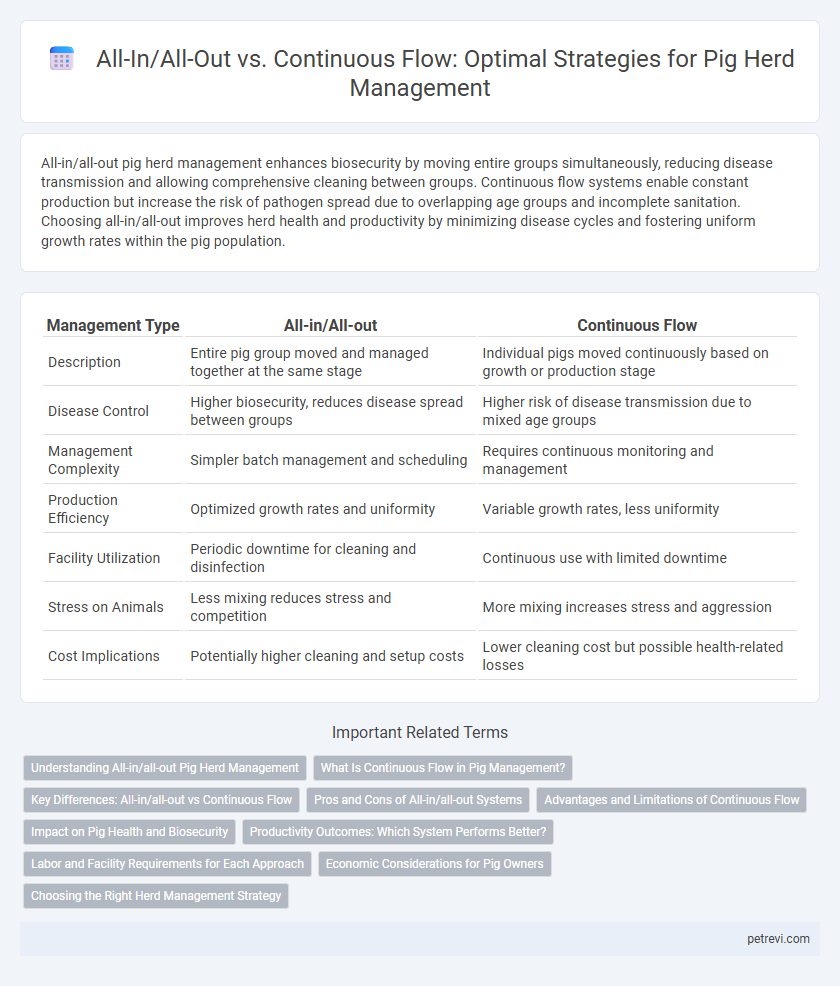

All-in/all-out pig herd management enhances biosecurity by moving entire groups simultaneously, reducing disease transmission and allowing comprehensive cleaning between groups. Continuous flow systems enable constant production but increase the risk of pathogen spread due to overlapping age groups and incomplete sanitation. Choosing all-in/all-out improves herd health and productivity by minimizing disease cycles and fostering uniform growth rates within the pig population.

Table of Comparison

| Management Type | All-in/All-out | Continuous Flow |

|---|---|---|

| Description | Entire pig group moved and managed together at the same stage | Individual pigs moved continuously based on growth or production stage |

| Disease Control | Higher biosecurity, reduces disease spread between groups | Higher risk of disease transmission due to mixed age groups |

| Management Complexity | Simpler batch management and scheduling | Requires continuous monitoring and management |

| Production Efficiency | Optimized growth rates and uniformity | Variable growth rates, less uniformity |

| Facility Utilization | Periodic downtime for cleaning and disinfection | Continuous use with limited downtime |

| Stress on Animals | Less mixing reduces stress and competition | More mixing increases stress and aggression |

| Cost Implications | Potentially higher cleaning and setup costs | Lower cleaning cost but possible health-related losses |

Understanding All-in/all-out Pig Herd Management

All-in/all-out (AIAO) pig herd management improves biosecurity by grouping pigs of the same age and moving them together through production stages, reducing disease transmission. This method allows thorough cleaning and disinfection of facilities between batches, lowering the risk of pathogen persistence compared to continuous flow systems. Implementing AIAO enhances growth performance and overall herd health by minimizing stress and cross-contamination among pigs.

What Is Continuous Flow in Pig Management?

Continuous flow in pig management refers to a production system where pigs of different ages are housed together and moved in and out of facilities at varying times, without strict separation by age groups. This approach contrasts with the all-in/all-out system, potentially increasing disease transmission risks due to overlapping age groups and less effective sanitation procedures. Continuous flow systems can complicate biosecurity measures and often result in uneven growth rates and health issues within the herd.

Key Differences: All-in/all-out vs Continuous Flow

All-in/all-out pig herd management involves moving groups of pigs through production stages together, allowing thorough cleaning and reducing disease spread, whereas continuous flow introduces pigs into facilities at different times, increasing biosecurity risks. The all-in/all-out system promotes better control over herd health and improved growth performance by minimizing pathogen transmission between groups. Continuous flow systems may lead to higher mortality rates and inconsistent growth due to overlapping age groups and increased exposure to infectious agents.

Pros and Cons of All-in/all-out Systems

All-in/all-out systems in pig herd management enhance biosecurity by minimizing disease transmission through complete depopulation and thorough cleaning between groups. This method improves growth performance and uniformity by grouping pigs of similar age and health status but requires strict scheduling and may reduce facility flexibility. However, the need for downtime between batches can decrease overall production capacity compared to continuous flow systems.

Advantages and Limitations of Continuous Flow

Continuous flow pig herd management allows for ongoing production without halting operations between batches, optimizing facility utilization and reducing downtime. However, this method increases the risk of disease transmission since pigs of different ages share the same environment, complicating biosecurity measures. It may also lead to uneven growth rates and variability in herd performance due to mixed-age groups and inconsistent management practices.

Impact on Pig Health and Biosecurity

All-in/all-out pig herd management significantly reduces disease transmission by allowing thorough cleaning and disinfection between groups, enhancing biosecurity and improving overall pig health. Continuous flow systems increase the risk of pathogen persistence and cross-contamination as pigs of different ages share environments, leading to higher incidence of respiratory and enteric diseases. Implementing all-in/all-out practices supports stronger herd immunity and minimizes outbreaks, crucial for sustainable pig production.

Productivity Outcomes: Which System Performs Better?

All-in/all-out pig herd management significantly improves productivity by minimizing disease transmission and promoting uniform growth rates, leading to higher feed efficiency and reduced mortality. Continuous flow systems often face challenges with pathogen buildup and inconsistent pig weights, resulting in lower overall performance metrics. Research shows all-in/all-out operations achieve better average daily gains and shorter production cycles, enhancing overall herd productivity.

Labor and Facility Requirements for Each Approach

All-in/all-out pig herd management requires intensive labor during batch transitions for thorough cleaning and disinfection, minimizing disease transmission while reducing ongoing labor needs. Facility design for all-in/all-out systems must support complete emptying of pig spaces between groups, including specialized cleaning equipment and dedicated downtime areas. Continuous flow systems demand steady labor input, with ongoing health monitoring and cleaning, and facilities designed for partial occupancy, posing challenges for disease control and requiring greater vigilance in routine maintenance.

Economic Considerations for Pig Owners

All-in/all-out pig herd management improves economic efficiency by reducing disease transmission, leading to lower veterinary costs and higher growth performance. Continuous flow systems may increase the risk of infections, causing increased mortality and treatment expenses that reduce overall profitability. Optimizing batch production schedules maximizes facility utilization and feed conversion rates, directly enhancing financial returns for pig owners.

Choosing the Right Herd Management Strategy

Choosing the right herd management strategy for pigs involves evaluating All-in/All-out (AIAO) and Continuous Flow systems based on biosecurity, productivity, and disease control. AIAO enhances health by moving pigs through production stages simultaneously, reducing pathogen transmission and improving growth rates. Continuous Flow allows for flexible production but increases disease risk due to mixed-age groups and prolonged pathogen persistence in facilities.

All-in/all-out vs Continuous flow for Pig herd management Infographic

petrevi.com

petrevi.com