Spot cooling targets specific areas on pigs, effectively reducing heat stress by directly cooling the animal's body, which leads to improved comfort and productivity. Tunnel ventilation provides a continuous flow of air throughout the entire building, promoting evaporative cooling and maintaining overall barn temperature and air quality. Combining spot cooling with tunnel ventilation often yields the best results, optimizing pig welfare and minimizing the negative effects of heat stress.

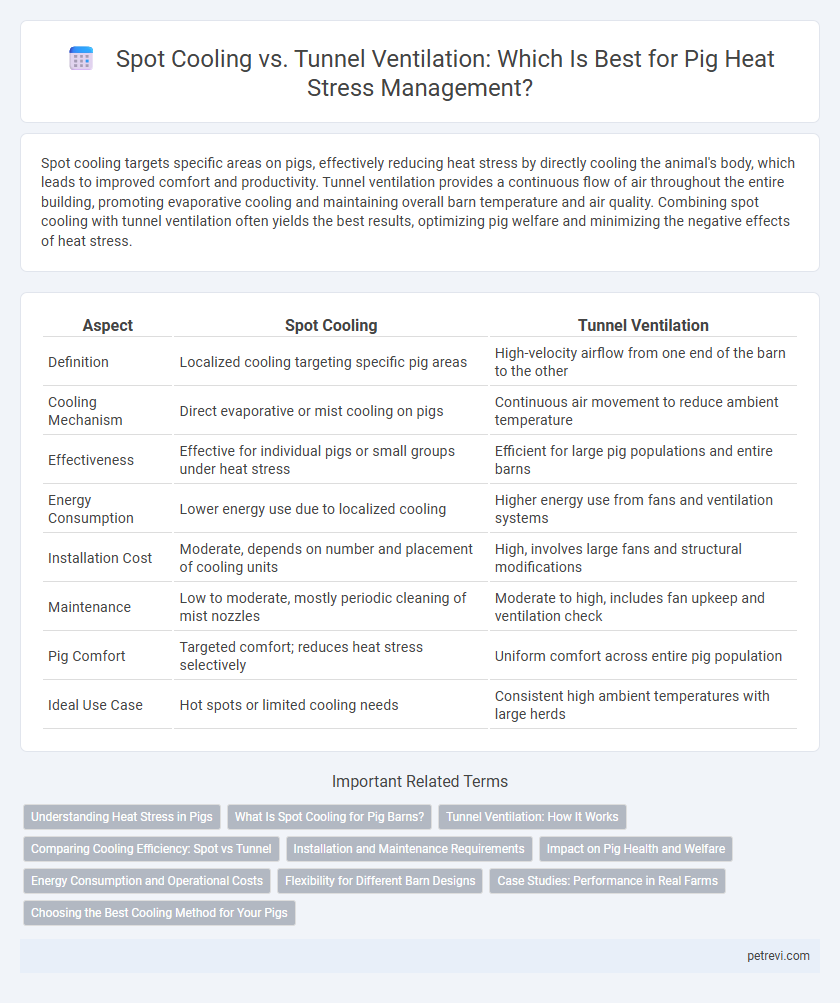

Table of Comparison

| Aspect | Spot Cooling | Tunnel Ventilation |

|---|---|---|

| Definition | Localized cooling targeting specific pig areas | High-velocity airflow from one end of the barn to the other |

| Cooling Mechanism | Direct evaporative or mist cooling on pigs | Continuous air movement to reduce ambient temperature |

| Effectiveness | Effective for individual pigs or small groups under heat stress | Efficient for large pig populations and entire barns |

| Energy Consumption | Lower energy use due to localized cooling | Higher energy use from fans and ventilation systems |

| Installation Cost | Moderate, depends on number and placement of cooling units | High, involves large fans and structural modifications |

| Maintenance | Low to moderate, mostly periodic cleaning of mist nozzles | Moderate to high, includes fan upkeep and ventilation check |

| Pig Comfort | Targeted comfort; reduces heat stress selectively | Uniform comfort across entire pig population |

| Ideal Use Case | Hot spots or limited cooling needs | Consistent high ambient temperatures with large herds |

Understanding Heat Stress in Pigs

Spot cooling targets specific pigs by delivering localized airflow or mist to reduce body temperature, effectively alleviating immediate heat stress. Tunnel ventilation circulates air through the entire pig housing, maintaining a consistent cooler environment and preventing heat buildup. Both methods influence pigs' thermoregulation by optimizing convective and evaporative heat loss, crucial for maintaining productivity and welfare during high temperatures.

What Is Spot Cooling for Pig Barns?

Spot cooling for pig barns targets specific heat-stressed areas using localized devices such as misting fans or evaporative coolers, effectively reducing pigs' core temperature. This method enhances thermal comfort by directly cooling the animals rather than the entire barn environment, improving feed intake and growth rates. Spot cooling systems often incorporate sensors to monitor temperature and humidity, enabling precise control and energy efficiency in heat mitigation strategies.

Tunnel Ventilation: How It Works

Tunnel ventilation reduces heat stress in pigs by creating a high-velocity airflow that rapidly removes excess body heat and moisture. Fans positioned at one end of the barn pull fresh air through the building, enhancing convective cooling and maintaining a consistent temperature. This method improves animal comfort and performance compared to spot cooling, which targets limited areas rather than the entire environment.

Comparing Cooling Efficiency: Spot vs Tunnel

Spot cooling targets specific areas of high heat load on pigs, delivering localized airflow that rapidly reduces skin temperature and mitigates heat stress more effectively in confined spaces. Tunnel ventilation circulates large volumes of air through pig housing, maintaining a consistent cooling environment but may struggle with uneven airflow distribution, leading to variable cooling efficiency across the pen. Studies indicate spot cooling can reduce pig body temperature by up to 2degC faster than tunnel ventilation, enhancing thermal comfort during acute heat episodes.

Installation and Maintenance Requirements

Spot cooling systems for pigs require localized installation near heat-prone areas, involving targeted fans or misters that are relatively easy to set up and maintain with routine cleaning of nozzles and filters. Tunnel ventilation demands comprehensive ducting and high-capacity exhaust fans installed along the barn's length, necessitating more complex setup and regular inspection of motorized components, belts, and electrical systems to ensure optimal airflow. Maintenance for spot cooling is generally less intensive with lower costs, while tunnel ventilation requires systematic upkeep to prevent airflow obstruction and mechanical failure.

Impact on Pig Health and Welfare

Spot cooling directly targets high-temperature zones, effectively reducing pig core body temperatures and minimizing heat stress-related illnesses. Tunnel ventilation enhances overall barn airflow, promoting consistent temperature control and improved air quality, which decreases respiratory issues and supports better pig welfare. Combining precise cooling methods with optimized ventilation systems ensures a healthier environment, reducing mortality rates and enhancing growth performance in pigs under heat stress conditions.

Energy Consumption and Operational Costs

Spot cooling targets pigs individually, significantly reducing energy consumption by cooling specific areas rather than an entire building, making it more cost-efficient for managing heat stress. Tunnel ventilation moves large volumes of air through pig barns, increasing energy costs due to high-power fans running continuously but improving overall barn temperature and air quality. Energy consumption for tunnel ventilation can be up to three times higher compared to spot cooling, directly impacting operational costs in pig farming operations.

Flexibility for Different Barn Designs

Spot cooling offers targeted temperature control and greater flexibility for various pig barn layouts, easily adapting to specific heat stress zones. Tunnel ventilation relies on a linear airflow system suited for elongated barns, providing uniform cooling but limited adaptability to complex barn geometries. Combining spot cooling with tunnel ventilation enhances overall heat stress management by accommodating diverse barn configurations and pig comfort needs.

Case Studies: Performance in Real Farms

Case studies on pig heat stress reveal that spot cooling systems, such as localized evaporative coolers, significantly lower microclimate temperatures directly around pigs, improving feed intake and reducing respiratory rates. Tunnel ventilation, widely implemented in commercial farms, enhances overall airflow, effectively decreasing barn temperatures and ammonia levels, resulting in better growth performance and lower mortality during heat waves. Comparative analyses indicate that integrating spot cooling within tunnel-ventilated barns yields optimal thermal comfort and productivity under extreme heat stress conditions.

Choosing the Best Cooling Method for Your Pigs

Spot cooling targets specific heat-stressed pigs using localized fans or misting systems, providing immediate relief and reducing heat strain during peak temperatures. Tunnel ventilation circulates air through a barn, creating a consistent airflow that lowers ambient temperature and improves overall pig comfort on a broader scale. Choosing spot cooling versus tunnel ventilation depends on farm size, infrastructure, and the severity of heat stress, with tunnel ventilation favored for large-scale operations and spot cooling suited for targeted, cost-effective management.

Spot cooling vs Tunnel ventilation for Pig heat stress Infographic

petrevi.com

petrevi.com