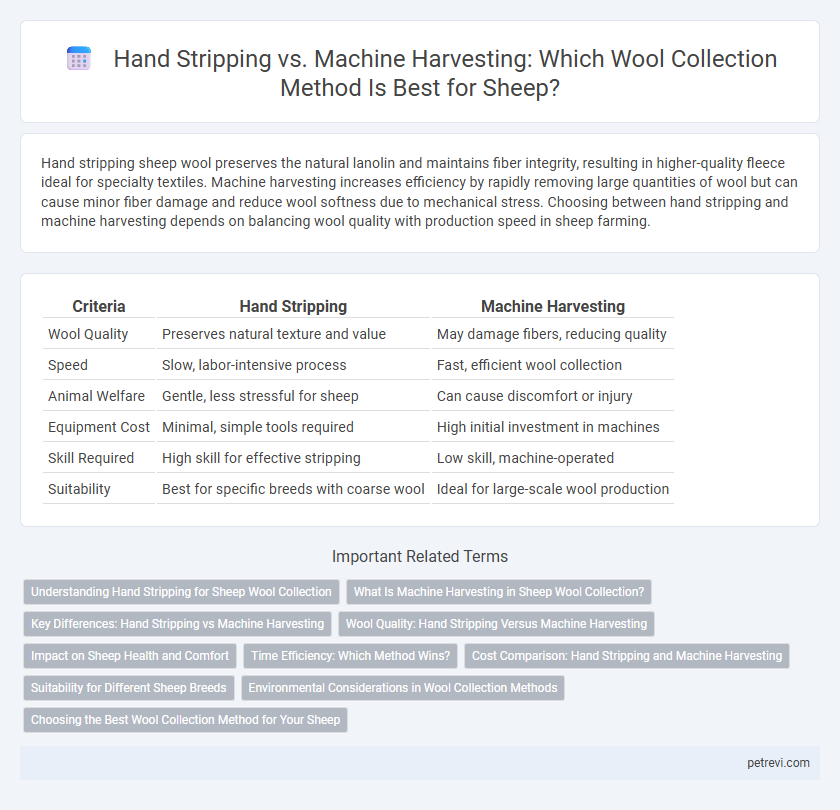

Hand stripping sheep wool preserves the natural lanolin and maintains fiber integrity, resulting in higher-quality fleece ideal for specialty textiles. Machine harvesting increases efficiency by rapidly removing large quantities of wool but can cause minor fiber damage and reduce wool softness due to mechanical stress. Choosing between hand stripping and machine harvesting depends on balancing wool quality with production speed in sheep farming.

Table of Comparison

| Criteria | Hand Stripping | Machine Harvesting |

|---|---|---|

| Wool Quality | Preserves natural texture and value | May damage fibers, reducing quality |

| Speed | Slow, labor-intensive process | Fast, efficient wool collection |

| Animal Welfare | Gentle, less stressful for sheep | Can cause discomfort or injury |

| Equipment Cost | Minimal, simple tools required | High initial investment in machines |

| Skill Required | High skill for effective stripping | Low skill, machine-operated |

| Suitability | Best for specific breeds with coarse wool | Ideal for large-scale wool production |

Understanding Hand Stripping for Sheep Wool Collection

Hand stripping for sheep wool collection involves manually pulling out the wool to remove dead or loose fibers, preserving the quality and natural lanolin content of the fleece. This traditional technique is especially effective for specific breeds like Border Leicester and Herdwick, which produce more delicate and coarse fibers. Hand stripping minimizes damage to the fleece and skin, resulting in high-quality wool preferred for specialty textiles and hand-spinning.

What Is Machine Harvesting in Sheep Wool Collection?

Machine harvesting in sheep wool collection involves using specialized shearing equipment designed to efficiently remove fleece from sheep with minimal stress. This method typically employs electric-powered clippers or rotary shears that speed up the shearing process compared to traditional hand stripping. Machine harvesting ensures consistent wool length and quality, making it a preferred choice for large-scale wool producers seeking productivity and uniformity.

Key Differences: Hand Stripping vs Machine Harvesting

Hand stripping involves manually plucking the wool from sheep, preserving the natural fiber structure and maintaining the fleece's quality for handspinners and specialty wool markets. Machine harvesting uses electric clippers that quickly shear wool, making it efficient for large-scale operations but can lead to fiber damage and less uniformity. The key differences lie in fiber integrity, wool quality, and production speed, with hand stripping favoring premium fleece and machine harvesting suited for volume.

Wool Quality: Hand Stripping Versus Machine Harvesting

Hand stripping preserves the natural lanolin and minimizes fiber damage, resulting in higher-quality wool with enhanced softness and durability. Machine harvesting often leads to fiber breakage and loss of crimp integrity, reducing overall wool quality and value. Optimal wool collection techniques prioritize maintaining fiber strength and cleanliness, critical for premium textile production.

Impact on Sheep Health and Comfort

Hand stripping preserves the natural oils and lanolin in sheep's wool, promoting healthier skin and reducing irritation compared to machine harvesting. Machine harvesting can cause nicks, cuts, and stress to the sheep due to the mechanical blades, potentially leading to infections and discomfort. Maintaining sheep health and comfort is critical; hand stripping supports this by being gentler and less invasive during wool collection.

Time Efficiency: Which Method Wins?

Hand stripping sheep wool requires significant manual labor and time, making it less efficient for large-scale operations. Machine harvesting, using electric shears or clippers, dramatically reduces the time needed to collect wool from an entire flock. For optimal time efficiency, commercial sheep farms predominantly rely on machine harvesting to maximize wool yield within shorter time frames.

Cost Comparison: Hand Stripping and Machine Harvesting

Hand stripping of sheep wool requires minimal initial investment but demands higher labor costs due to its time-intensive nature, making it less cost-effective for large-scale operations. Machine harvesting involves significant upfront expenses for equipment purchase and maintenance but reduces labor costs and increases throughput, benefiting commercial wool producers. Overall, hand stripping suits small flocks and specialty wool markets, while machine harvesting proves economically advantageous for extensive wool production.

Suitability for Different Sheep Breeds

Hand stripping offers precise wool removal suited for shedding breeds like Border Leicester and Shetland, preserving fleece quality and skin health. Machine harvesting efficiently processes dense, continuous fleeces typical of Merino and Romney sheep, optimizing yield but risking fiber damage on fine or coarse wools. Selecting the appropriate method depends on breed-specific fleece characteristics, balancing wool integrity and collection efficiency.

Environmental Considerations in Wool Collection Methods

Hand stripping minimizes environmental impact by reducing energy consumption and avoiding the use of mechanized tools that produce noise pollution. Machine harvesting increases efficiency but relies on electricity or fuel, contributing to carbon emissions and potential habitat disruption due to equipment storage and maintenance. Choosing sustainable wool collection methods like hand stripping supports animal welfare and lowers the carbon footprint of the wool industry.

Choosing the Best Wool Collection Method for Your Sheep

Hand stripping preserves the natural lanolin and texture of the fleece, making it ideal for heritage sheep breeds and specialty wool products. Machine harvesting offers efficiency and speed, suitable for large-scale operations but may cause stress or skin damage if not handled properly. Selecting the best wool collection method depends on sheep breed, wool quality goals, and farm resources to balance animal welfare with production needs.

Hand Stripping vs Machine Harvesting for Sheep Wool Collection Infographic

petrevi.com

petrevi.com