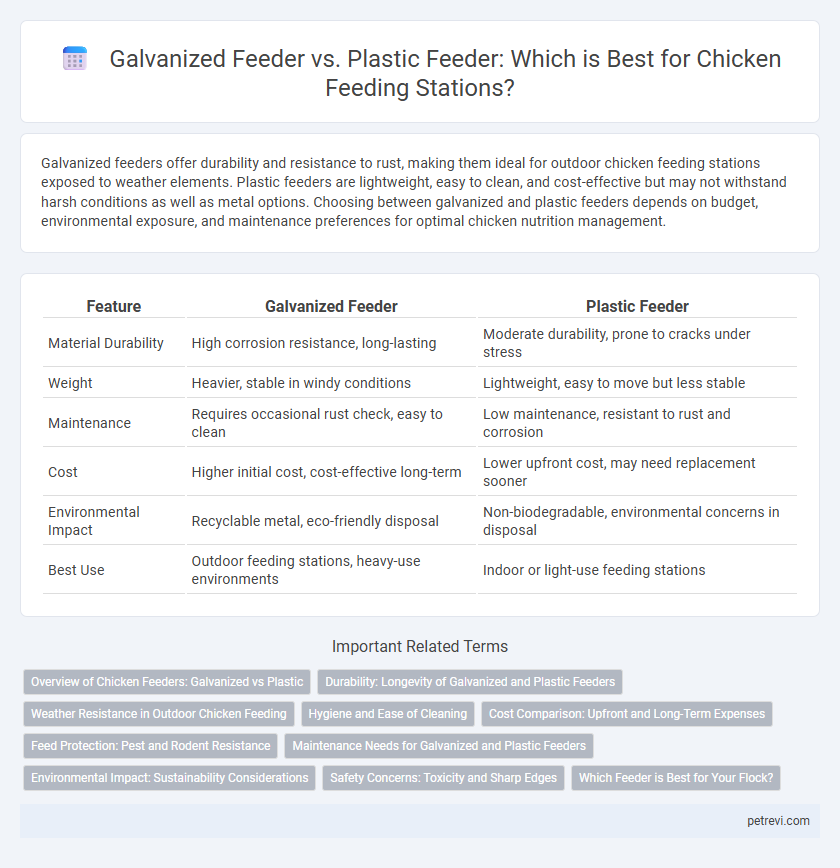

Galvanized feeders offer durability and resistance to rust, making them ideal for outdoor chicken feeding stations exposed to weather elements. Plastic feeders are lightweight, easy to clean, and cost-effective but may not withstand harsh conditions as well as metal options. Choosing between galvanized and plastic feeders depends on budget, environmental exposure, and maintenance preferences for optimal chicken nutrition management.

Table of Comparison

| Feature | Galvanized Feeder | Plastic Feeder |

|---|---|---|

| Material Durability | High corrosion resistance, long-lasting | Moderate durability, prone to cracks under stress |

| Weight | Heavier, stable in windy conditions | Lightweight, easy to move but less stable |

| Maintenance | Requires occasional rust check, easy to clean | Low maintenance, resistant to rust and corrosion |

| Cost | Higher initial cost, cost-effective long-term | Lower upfront cost, may need replacement sooner |

| Environmental Impact | Recyclable metal, eco-friendly disposal | Non-biodegradable, environmental concerns in disposal |

| Best Use | Outdoor feeding stations, heavy-use environments | Indoor or light-use feeding stations |

Overview of Chicken Feeders: Galvanized vs Plastic

Galvanized chicken feeders are constructed with coated steel, providing durability and resistance to rust, making them ideal for outdoor use and long-term feeding efficiency. Plastic feeders offer lightweight, cost-effective solutions with ease of cleaning, but they may crack or degrade under extreme weather conditions. Selecting between galvanized and plastic feeders depends on factors such as environmental exposure, budget, and maintenance preferences for optimal chicken feeding station performance.

Durability: Longevity of Galvanized and Plastic Feeders

Galvanized feeders feature a robust metal construction resistant to rust and corrosion, extending their lifespan significantly in outdoor or humid environments. Plastic feeders, while lightweight and often more affordable, tend to degrade faster when exposed to sunlight and harsh weather conditions, reducing their overall durability. For long-term use and structural resilience, galvanized feeders generally offer superior longevity compared to plastic alternatives in chicken feeding stations.

Weather Resistance in Outdoor Chicken Feeding

Galvanized feeders offer superior weather resistance for outdoor chicken feeding stations due to their corrosion-resistant zinc coating, preventing rust in wet conditions and extending feeder lifespan. Plastic feeders, while lightweight and easy to clean, can degrade under prolonged UV exposure, becoming brittle and prone to cracking in harsh sunlight or cold weather. Choosing galvanized feeders ensures durability and consistent performance in diverse climates, minimizing maintenance and replacement costs.

Hygiene and Ease of Cleaning

Galvanized feeders offer superior durability and resistance to rust, ensuring long-term hygiene by preventing bacterial buildup in chicken feeding stations. Plastic feeders, although lightweight and often more affordable, can develop scratches and cracks that harbor dirt and pathogens, posing a hygiene risk if not cleaned meticulously. Cleaning galvanized feeders is typically easier due to their smooth metal surface, which resists stains and can withstand more rigorous washing compared to plastic feeders that may degrade over time with frequent cleaning.

Cost Comparison: Upfront and Long-Term Expenses

Galvanized feeders generally have a higher upfront cost compared to plastic feeders but offer greater durability and resistance to weather and corrosion, reducing replacement frequency and maintenance expenses over time. Plastic feeders are more affordable initially but may require frequent replacement due to cracking, UV damage, or wear, increasing long-term costs. Evaluating the total cost of ownership, galvanized feeders can prove more cost-effective for large or long-term chicken feeding operations.

Feed Protection: Pest and Rodent Resistance

Galvanized feeders provide superior feed protection by deterring pests and rodents through durable metal construction that resists gnawing and contamination. Plastic feeders can be more susceptible to damage from rodents, leading to feed spillage and increased risk of pest infestation. Choosing galvanized feeders enhances feed hygiene and reduces losses by effectively minimizing access to chickens' feed.

Maintenance Needs for Galvanized and Plastic Feeders

Galvanized feeders require periodic inspection for rust and corrosion, especially in humid or wet environments, to maintain durability and prevent contamination. Plastic feeders are easier to clean and resist rust but may degrade or crack over time when exposed to UV light or extreme temperatures. Both feeder types benefit from regular cleaning to prevent feed buildup and bacterial growth, ensuring a healthy feeding station for chickens.

Environmental Impact: Sustainability Considerations

Galvanized feeders, made from steel coated with zinc, tend to be more durable and recyclable, reducing waste and environmental footprint over time compared to plastic feeders which often degrade and contribute to microplastic pollution. Plastic feeders, while lightweight and inexpensive, typically have a shorter lifespan and pose greater challenges in landfill decomposition, impacting soil and water quality. Choosing galvanized feeders supports sustainability by promoting material reuse and minimizing long-term environmental harm in chicken feeding stations.

Safety Concerns: Toxicity and Sharp Edges

Galvanized feeders raise safety concerns due to potential zinc toxicity if the coating deteriorates, posing health risks to chickens, while plastic feeders are typically non-toxic but may degrade under UV exposure. Sharp edges on galvanized feeders can cause injuries to chickens, whereas plastic feeders generally have smoother surfaces, reducing the risk of cuts and abrasions. Selecting feeders involves balancing durability and safety, with plastic feeders often preferred to minimize toxicity and physical harm.

Which Feeder is Best for Your Flock?

Galvanized feeders offer superior durability and resistance to rust, making them ideal for outdoor chicken feeding stations exposed to weather elements. Plastic feeders are lightweight, easy to clean, and often cost-effective but may crack or degrade over time under harsh conditions. Choosing the best feeder depends on your flock size, environment, and maintenance preferences, with galvanized feeders preferred for long-term use and plastic feeders favored for convenience and budget.

Galvanized Feeder vs Plastic Feeder for Chicken Feeding Stations Infographic

petrevi.com

petrevi.com