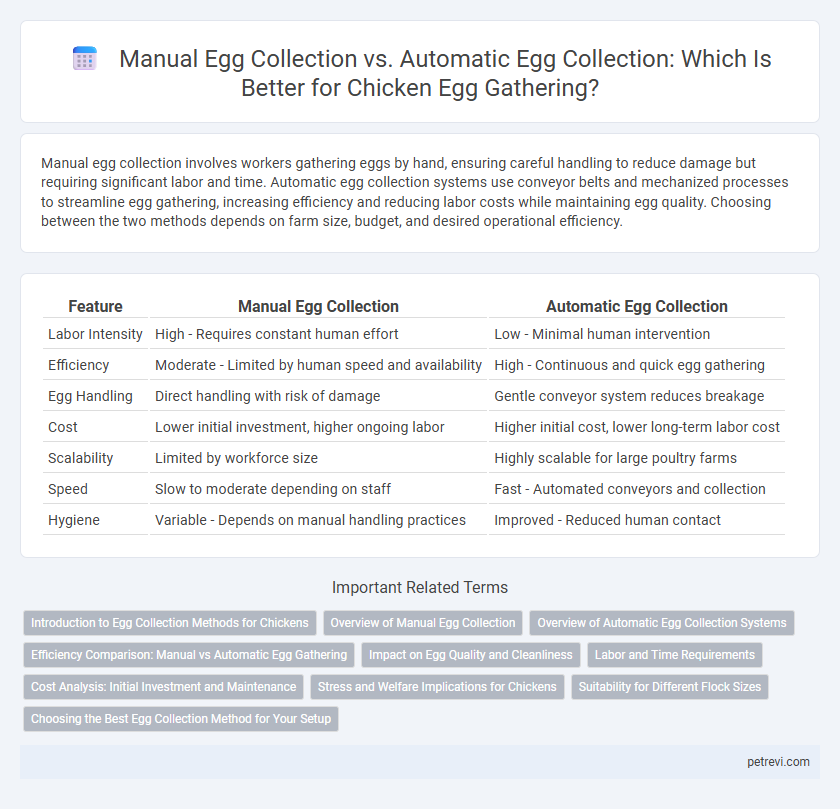

Manual egg collection involves workers gathering eggs by hand, ensuring careful handling to reduce damage but requiring significant labor and time. Automatic egg collection systems use conveyor belts and mechanized processes to streamline egg gathering, increasing efficiency and reducing labor costs while maintaining egg quality. Choosing between the two methods depends on farm size, budget, and desired operational efficiency.

Table of Comparison

| Feature | Manual Egg Collection | Automatic Egg Collection |

|---|---|---|

| Labor Intensity | High - Requires constant human effort | Low - Minimal human intervention |

| Efficiency | Moderate - Limited by human speed and availability | High - Continuous and quick egg gathering |

| Egg Handling | Direct handling with risk of damage | Gentle conveyor system reduces breakage |

| Cost | Lower initial investment, higher ongoing labor | Higher initial cost, lower long-term labor cost |

| Scalability | Limited by workforce size | Highly scalable for large poultry farms |

| Speed | Slow to moderate depending on staff | Fast - Automated conveyors and collection |

| Hygiene | Variable - Depends on manual handling practices | Improved - Reduced human contact |

Introduction to Egg Collection Methods for Chickens

Manual egg collection involves workers gathering eggs by hand, ensuring careful handling and immediate inspection for cracks or defects. Automatic egg collection systems use conveyors or rollers to transport eggs from nesting boxes to a central collection point, increasing efficiency and reducing labor costs. Both methods impact egg quality, farm productivity, and operational expenses in poultry farming.

Overview of Manual Egg Collection

Manual egg collection involves workers gathering eggs by hand directly from nest boxes, ensuring careful handling to minimize breakage and contamination. This method allows for immediate inspection of eggshell quality and cleanliness, supporting egg grading and selection processes. Manual collection is labor-intensive but provides flexibility in managing smaller operations and detecting nest issues promptly.

Overview of Automatic Egg Collection Systems

Automatic egg collection systems streamline poultry farm operations by using conveyor belts or rolling trays to transport eggs directly from nest boxes to centralized collection points, minimizing handling and reducing breakage. These systems integrate sensors and automated timers to optimize collection intervals, improving hygiene by limiting egg exposure to contaminants. Implementing automatic collection enhances labor efficiency, supports large-scale production, and maintains egg quality through consistent handling and timely removal from laying areas.

Efficiency Comparison: Manual vs Automatic Egg Gathering

Manual egg collection requires significant labor and time, often limiting the number of eggs gathered daily and increasing the risk of egg damage. Automatic egg collection systems improve efficiency by streamlining the gathering process, reducing labor costs, and minimizing egg breakage through mechanized conveyance. Farms utilizing automatic systems report higher throughput and better biosecurity, making it a more scalable solution for large-scale poultry operations.

Impact on Egg Quality and Cleanliness

Manual egg collection allows for careful handling, reducing the risk of cracks and maintaining higher egg quality, but it is labor-intensive and may increase variability in cleanliness due to human error. Automatic egg collection systems consistently reduce egg contamination by minimizing direct contact and exposure to soiled surfaces, enhancing overall cleanliness and uniformity in egg quality. However, automation requires precise calibration to prevent mechanical damage that could compromise shell integrity and freshness.

Labor and Time Requirements

Manual egg collection demands significant labor input, requiring workers to gather eggs by hand frequently throughout the day, which increases labor costs and time spent on egg retrieval. In contrast, automatic egg collection systems reduce human labor substantially by using conveyor belts or mechanized rollers to transport eggs directly from nests to collection points, saving time and improving efficiency. Time savings with automatic systems enhance productivity, allowing poultry operations to scale more effectively while minimizing the risk of egg breakage due to delayed collection.

Cost Analysis: Initial Investment and Maintenance

Manual egg collection requires minimal initial investment, typically involving basic tools and labor costs, but higher ongoing labor expenses can accumulate over time. Automatic egg collection systems demand a significant upfront cost for equipment installation and technology integration, yet they reduce labor costs and improve efficiency with lower maintenance expenditures. Over the long term, automatic systems often prove more cost-effective by optimizing egg handling while minimizing human labor and error rates.

Stress and Welfare Implications for Chickens

Manual egg collection often increases handling stress for chickens, potentially disrupting their natural behaviors and welfare due to frequent human interaction. In contrast, automatic egg collection systems minimize human contact, reducing stress and promoting better hens' welfare by maintaining a calmer environment. Studies show automated systems can decrease corticosterone levels, indicating lower stress and improved overall well-being in laying hens.

Suitability for Different Flock Sizes

Manual egg collection suits small to medium-sized chicken flocks, allowing careful handling and inspection of eggs, which reduces damage and contamination. Automatic egg collection systems are ideal for large-scale poultry farms, increasing efficiency and reducing labor costs by swiftly gathering eggs with minimal human intervention. Choosing between manual and automatic methods depends on flock size, farm budget, and operational priorities to optimize productivity and egg quality.

Choosing the Best Egg Collection Method for Your Setup

Manual egg collection offers precise control and reduced equipment costs, making it ideal for small-scale or backyard chicken keepers prioritizing hands-on care. Automatic egg collection systems enhance efficiency and hygiene by minimizing egg handling and damage, fitting larger commercial operations seeking to streamline production. Evaluating flock size, budget, and labor availability is essential to determine the most suitable method for optimal egg gathering performance.

Manual Egg Collection vs Automatic Egg Collection for Chicken Egg Gathering Infographic

petrevi.com

petrevi.com