Milking parlors offer structured, high-volume milking with human oversight, ensuring consistent milk quality and herd management. Robotic milkers provide automated, individualized milking sessions that improve animal welfare and allow cows to be milked on their own schedule. Both methods enhance efficiency, but robotic milkers reduce labor costs and enable real-time data tracking for health monitoring.

Table of Comparison

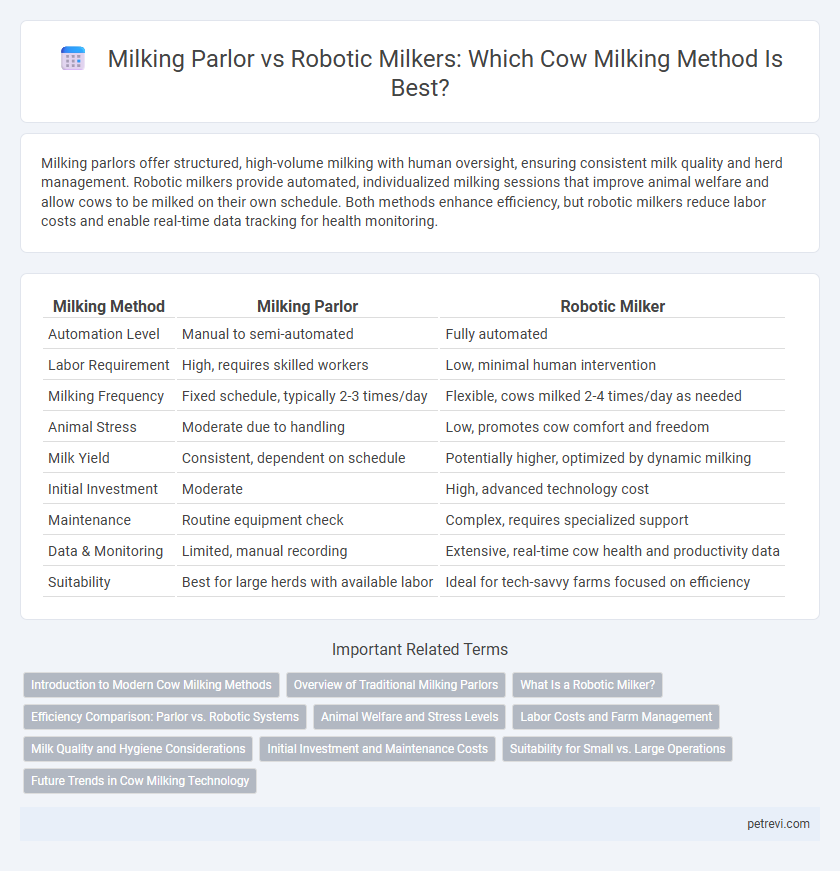

| Milking Method | Milking Parlor | Robotic Milker |

|---|---|---|

| Automation Level | Manual to semi-automated | Fully automated |

| Labor Requirement | High, requires skilled workers | Low, minimal human intervention |

| Milking Frequency | Fixed schedule, typically 2-3 times/day | Flexible, cows milked 2-4 times/day as needed |

| Animal Stress | Moderate due to handling | Low, promotes cow comfort and freedom |

| Milk Yield | Consistent, dependent on schedule | Potentially higher, optimized by dynamic milking |

| Initial Investment | Moderate | High, advanced technology cost |

| Maintenance | Routine equipment check | Complex, requires specialized support |

| Data & Monitoring | Limited, manual recording | Extensive, real-time cow health and productivity data |

| Suitability | Best for large herds with available labor | Ideal for tech-savvy farms focused on efficiency |

Introduction to Modern Cow Milking Methods

Modern cow milking methods include traditional milking parlors and robotic milkers, each enhancing efficiency and animal welfare. Milking parlors provide structured environments for group milking, improving throughput and hygiene, while robotic milkers offer automated, individual cow milking that adjusts to cow behavior and milking frequency. These advanced technologies optimize milk yield, reduce labor costs, and support sustainable dairy farm operations.

Overview of Traditional Milking Parlors

Traditional milking parlors are designed for batch milking multiple cows simultaneously, optimizing labor efficiency and herd management. These parlors utilize either herringbone, parallel, or rotary configurations, facilitating manual or semi-automated milking processes while ensuring cow comfort and hygiene. Despite rising automation, milking parlors remain prevalent in many dairy farms due to lower initial setup costs and straightforward maintenance requirements.

What Is a Robotic Milker?

A robotic milker is an automated system that uses advanced sensors and robotic arms to milk cows with minimal human intervention, improving efficiency and animal comfort. It allows cows to be milked individually based on their milking schedule and health data, enhancing milk quality and udder health. Robotic milking systems integrate with farm management software to monitor cow behavior, milk yield, and detect early signs of illness.

Efficiency Comparison: Parlor vs. Robotic Systems

Milking parlors achieve high throughput by allowing multiple cows to be milked simultaneously, optimizing labor but requiring fixed scheduling and significant manual oversight. Robotic milking systems enhance efficiency through continuous, on-demand milking, reducing labor costs and improving cow comfort by allowing voluntary milking frequency. Studies indicate robotic systems can increase milk yield per cow while decreasing milking time per session, but initial investment and maintenance costs may affect overall cost-effectiveness compared to traditional parlors.

Animal Welfare and Stress Levels

Robotic milkers enhance animal welfare by allowing cows to choose their own milking times, reducing stress associated with fixed schedules in traditional milking parlors. These systems monitor cow health parameters such as udder cleanliness and milk quality, promoting early detection of issues and personalized care. In contrast, conventional milking parlors often induce higher stress due to forced movement and handling, which can negatively impact milk yield and animal well-being.

Labor Costs and Farm Management

Robotic milkers reduce labor costs significantly by automating the milking process, allowing fewer farmworkers to manage larger herds efficiently. Milking parlors require more manual labor and supervision, increasing labor expenses and complicating scheduling. Farm management benefits from robotic systems through data collection and real-time monitoring, optimizing herd health and milk production without intensive human intervention.

Milk Quality and Hygiene Considerations

Milking parlors provide controlled environments that enhance milk quality by minimizing contamination and allowing for consistent hygiene practices, such as teat cleaning and prompt milk cooling. Robotic milkers employ automated cleaning systems and sensors to detect milk quality parameters in real time, reducing human error and improving udder health monitoring. Both methods aim to optimize hygiene, but robotic systems offer advanced data-driven management that can lead to improved milk quality consistency.

Initial Investment and Maintenance Costs

Milking parlors require a lower initial investment, typically ranging from $150,000 to $300,000 for a mid-sized dairy farm, while robotic milkers can cost between $180,000 and $250,000 per unit, often necessitating multiple units for effective operation. Maintenance costs for milking parlors are relatively lower, averaging around 5-10% of the initial investment annually, compared to robotic milkers, which can incur maintenance expenses upwards of 15%, due to complex electronics and software updates. Choosing between the two methods depends on the farm's scale, labor availability, and long-term cost efficiency considerations.

Suitability for Small vs. Large Operations

Milking parlors are ideal for large-scale dairy farms, offering high throughput and efficient herd management with multiple cows milked simultaneously. Robotic milkers suit small to medium-sized operations by allowing individual cow monitoring, reducing labor costs, and providing flexibility in milking times. The choice depends on farm size, labor availability, and investment capacity, with parlors excelling in volume and robots enhancing precision and animal welfare.

Future Trends in Cow Milking Technology

Robotic milkers are transforming the future of cow milking by enabling automated, precise milking schedules tailored to individual cows, improving milk yield and animal welfare. Milking parlors remain relevant for large-scale operations but face increasing competition due to labor-intensive requirements and less flexibility. Integration of AI and IoT in robotic systems optimizes herd management, reduces human error, and supports sustainable dairy farming practices.

Milking Parlor vs Robotic Milker for Cow Milking Method Infographic

petrevi.com

petrevi.com