Deep pit manure storage offers a compact and cost-effective solution for pig waste management, reducing odor emissions and minimizing groundwater contamination. Lagoon systems require larger land areas and carry higher risks of nutrient runoff but provide more natural waste treatment through microbial activity over time. Choosing between these systems depends on farm size, environmental regulations, and long-term sustainability goals.

Table of Comparison

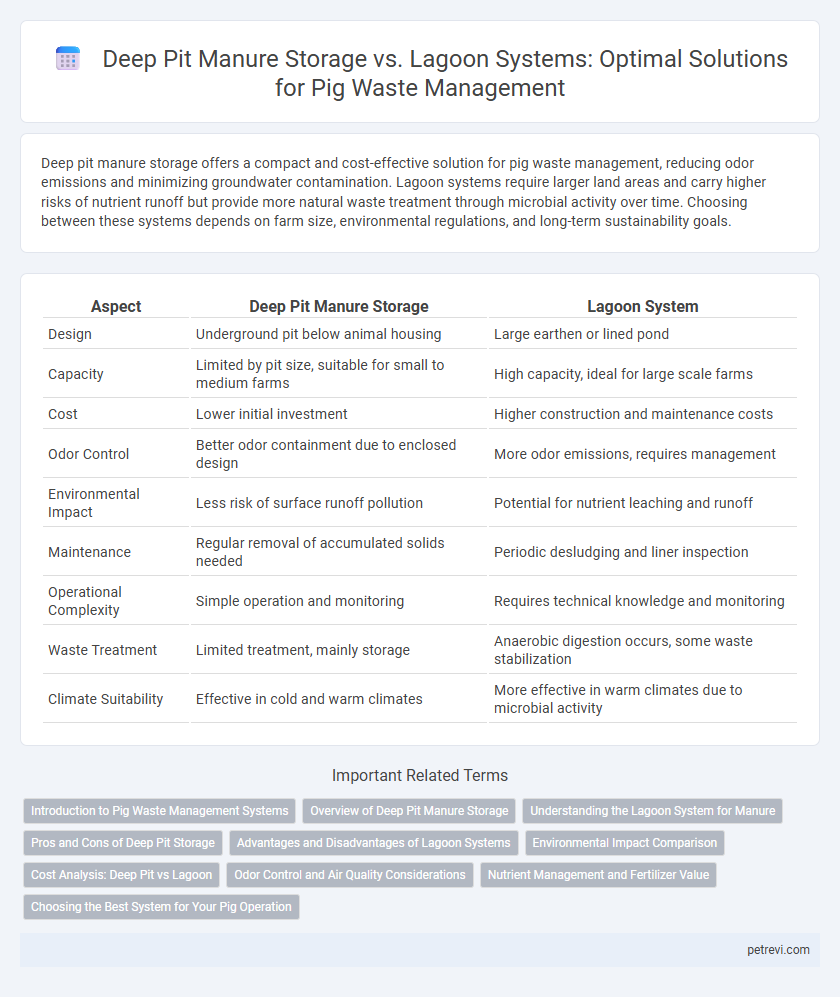

| Aspect | Deep Pit Manure Storage | Lagoon System |

|---|---|---|

| Design | Underground pit below animal housing | Large earthen or lined pond |

| Capacity | Limited by pit size, suitable for small to medium farms | High capacity, ideal for large scale farms |

| Cost | Lower initial investment | Higher construction and maintenance costs |

| Odor Control | Better odor containment due to enclosed design | More odor emissions, requires management |

| Environmental Impact | Less risk of surface runoff pollution | Potential for nutrient leaching and runoff |

| Maintenance | Regular removal of accumulated solids needed | Periodic desludging and liner inspection |

| Operational Complexity | Simple operation and monitoring | Requires technical knowledge and monitoring |

| Waste Treatment | Limited treatment, mainly storage | Anaerobic digestion occurs, some waste stabilization |

| Climate Suitability | Effective in cold and warm climates | More effective in warm climates due to microbial activity |

Introduction to Pig Waste Management Systems

Pig waste management systems primarily include deep pit manure storage and lagoon systems, both designed to effectively contain and treat pig manure while minimizing environmental impact. Deep pit manure storage involves underground pits beneath pig housing, capturing waste in a concentrated area and facilitating easier manure removal and nutrient recycling. Lagoon systems utilize large, lined ponds allowing anaerobic digestion to break down waste, reducing odors and pathogens while enabling long-term storage and potential biogas recovery.

Overview of Deep Pit Manure Storage

Deep pit manure storage in pig farming involves collecting and storing manure in a deep, sealed pit beneath the animal housing, minimizing odor emission and reducing nutrient runoff compared to traditional lagoon systems. This method enhances nitrogen preservation by limiting exposure to air and supports efficient waste handling through periodic agitation and pumping. Deep pit storage systems require careful design to prevent structural issues and groundwater contamination, making them suitable for farms with limited land area for waste management.

Understanding the Lagoon System for Manure

The lagoon system for pig manure management involves storing waste in large, anaerobic ponds designed to treat and stabilize manure through microbial activity, reducing odors and nutrient concentrations over time. These lagoons are typically lined to prevent groundwater contamination and allow for seasonal storage, minimizing environmental impact. Proper management of lagoon systems includes regular monitoring of nutrient levels and maintaining structural integrity to optimize manure treatment and support sustainable pig farming operations.

Pros and Cons of Deep Pit Storage

Deep pit manure storage offers efficient space utilization and reduced odor emissions compared to surface systems, making it suitable for large-scale pig operations. It minimizes labor by allowing manure to accumulate over time, but risks include potential structural failure and increased ammonia volatilization if not properly maintained. While deep pits lower pathogen exposure by limiting manure agitation, they require careful monitoring to prevent environmental contamination and ensure animal welfare.

Advantages and Disadvantages of Lagoon Systems

Lagoon systems for pig waste management offer cost-effective storage and natural treatment through microbial processes, reducing nutrient load before field application. They require significant land area and pose risks of leakage or overflow, potentially contaminating groundwater and surface water. Maintenance challenges include odor control and vulnerability to adverse weather conditions, which can affect system efficiency and environmental compliance.

Environmental Impact Comparison

Deep pit manure storage in pig farming reduces odor emissions by containing waste beneath the barn floor, limiting ammonia volatilization and minimizing surface nutrient runoff, but it poses risks of groundwater contamination if not properly managed. Lagoon systems offer effective dilution and microbial breakdown of pig waste, lowering nitrogen and phosphorus loads before land application; however, they can emit methane and nitrous oxide, potent greenhouse gases contributing to climate change. Environmental impact assessments reveal that deep pit systems have a smaller carbon footprint, whereas lagoons require careful aeration and coverage to mitigate emissions and protect local water quality.

Cost Analysis: Deep Pit vs Lagoon

Deep pit manure storage systems typically incur higher initial construction costs due to excavation and durable concrete requirements but offer lower long-term maintenance expenses compared to lagoon systems. Lagoon systems involve lower upfront investment but demand continuous operational costs for aeration, desludging, and environmental compliance, potentially increasing total expenses over time. Evaluating cost-effectiveness depends on farm size, regional climate, and regulatory constraints, with deep pits favoring intensive operations and lagoons suited for larger, extensive setups.

Odor Control and Air Quality Considerations

Deep pit manure storage offers enhanced odor control through anaerobic digestion, reducing volatile organic compounds (VOCs) and ammonia emissions compared to lagoon systems. Lagoon systems often emit higher levels of odorous gases and contribute more significantly to air quality degradation due to open-air exposure and surface agitation. Implementing covers or aerated lagoons can improve odor containment and mitigate negative air quality impacts associated with pig waste management.

Nutrient Management and Fertilizer Value

Deep pit manure storage captures higher concentrations of nutrients such as nitrogen, phosphorus, and potassium, enhancing fertilizer value compared to lagoon systems where nutrient losses occur due to volatilization and dilution. The deep pit system stabilizes manure nutrients over time, providing a consistent and nutrient-rich fertilizer that supports precise nutrient management plans. Lagoon systems often experience nutrient stratification and reduced total nutrient availability, limiting their effectiveness for optimized crop fertilization.

Choosing the Best System for Your Pig Operation

Deep pit manure storage offers a compact, odor-controlled solution ideal for high-density pig operations with limited land availability, reducing labor and equipment needs by accumulating waste beneath the barn floor. Lagoon systems provide cost-effective, large-capacity storage with natural anaerobic digestion, suitable for operations with ample land and the ability to manage emissions through aeration or biological treatment. Selecting the best system depends on farm size, environmental regulations, land resources, and budget constraints, ensuring optimal nutrient management and operational efficiency for sustainable pig waste handling.

Deep pit manure storage vs Lagoon system for Pig waste management Infographic

petrevi.com

petrevi.com