Automatic milking systems enhance efficiency by allowing cows to be milked without human intervention, increasing milking frequency and improving udder health through consistent routines. Traditional milking relies on manual labor, which can lead to variable milk output and increased stress for the cows due to irregular milking times. The adoption of automatic systems supports better milk quality and farm productivity by integrating advanced sensor technologies for monitoring cow health in real-time.

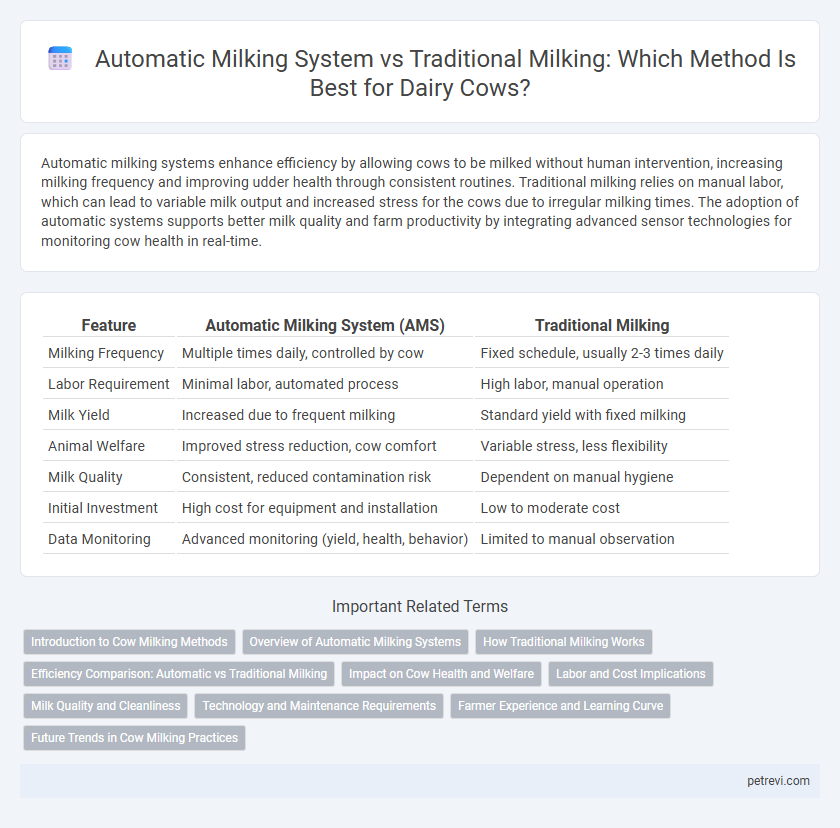

Table of Comparison

| Feature | Automatic Milking System (AMS) | Traditional Milking |

|---|---|---|

| Milking Frequency | Multiple times daily, controlled by cow | Fixed schedule, usually 2-3 times daily |

| Labor Requirement | Minimal labor, automated process | High labor, manual operation |

| Milk Yield | Increased due to frequent milking | Standard yield with fixed milking |

| Animal Welfare | Improved stress reduction, cow comfort | Variable stress, less flexibility |

| Milk Quality | Consistent, reduced contamination risk | Dependent on manual hygiene |

| Initial Investment | High cost for equipment and installation | Low to moderate cost |

| Data Monitoring | Advanced monitoring (yield, health, behavior) | Limited to manual observation |

Introduction to Cow Milking Methods

Automatic milking systems (AMS) use robotic technology to milk cows, enhancing efficiency and reducing labor costs compared to traditional milking methods, which rely on manual or parlor-based techniques. AMS provides real-time monitoring of cow health and milk quality through sensors, increasing overall herd management precision. Traditional milking remains widespread in smaller farms due to lower initial investment, while AMS adoption grows in large-scale dairy operations seeking automation and data-driven insights.

Overview of Automatic Milking Systems

Automatic Milking Systems (AMS) utilize robotic technology to milk cows, ensuring precise and consistent milking schedules that optimize udder health and milk yield. These systems incorporate sensors and data analytics to monitor individual cow behavior, health indicators, and milk quality in real time. Compared to traditional milking methods, AMS reduces labor costs, minimizes human error, and enhances animal welfare through stress-free, voluntary milking processes.

How Traditional Milking Works

Traditional milking involves manually extracting milk from cows using hand milking or milking machines operated by farmers, relying on physical labor and direct animal handling. The process requires cleaning the udder, attaching the milking equipment, and monitoring milk flow to ensure hygiene and cow comfort. Despite being labor-intensive, traditional milking allows farmers to detect health issues early through tactile and visual inspection.

Efficiency Comparison: Automatic vs Traditional Milking

Automatic milking systems (AMS) enhance efficiency by enabling cows to be milked multiple times daily without human intervention, increasing milk yield by up to 20%. Traditional milking relies on scheduled manual labor, limiting milking frequency and often resulting in lower overall productivity. AMS also reduces labor costs and cow stress, further improving operational efficiency compared to conventional methods.

Impact on Cow Health and Welfare

Automatic milking systems improve cow health by enabling more frequent and gentle milking, reducing stress and mastitis incidence compared to traditional milking methods. These systems monitor individual cow health metrics such as milk yield and somatic cell count, allowing early detection of potential health issues. Traditional milking often leads to inconsistent milking schedules and increased handling stress, negatively impacting overall cow welfare.

Labor and Cost Implications

Automatic milking systems reduce labor requirements significantly by enabling cows to be milked without human intervention, leading to lower long-term labor costs despite higher initial investments. Traditional milking relies heavily on manual labor, increasing ongoing wages and limiting farm scalability. While automatic systems demand upfront technology expenses and maintenance, they optimize labor efficiency and can decrease overall operational costs over time.

Milk Quality and Cleanliness

Automatic milking systems enhance milk quality and cleanliness by reducing human contact and promoting consistent hygiene standards through automated cleaning cycles. Traditional milking methods often involve manual handling that can introduce contaminants and variability in milk cleanliness. Studies show that automatic systems maintain lower bacterial counts and improve overall milk quality compared to conventional milking practices.

Technology and Maintenance Requirements

Automatic milking systems (AMS) utilize advanced robotics and sensor technology to enhance milking efficiency, reducing labor and improving cow health monitoring through real-time data analytics. Traditional milking methods require manual labor and regular equipment cleaning, often leading to variable milking consistency and higher human resource costs. AMS demands routine technical maintenance and software updates to ensure optimal performance, while traditional milking equipment involves basic mechanical upkeep with less complex troubleshooting needs.

Farmer Experience and Learning Curve

Automatic milking systems revolutionize the farmer experience by offering hands-free operation, reducing manual labor, and enabling round-the-clock milking, though they require initial investment in technology and training. Traditional milking relies on established manual techniques with a shorter learning curve but demands more physical effort and time commitment. Farmers adopting automatic systems benefit from data-driven herd management but must navigate a steeper learning curve involving system maintenance and software proficiency.

Future Trends in Cow Milking Practices

Automatic milking systems (AMS) harness advanced robotics and sensor technology to increase efficiency, improve animal health monitoring, and reduce labor costs compared to traditional milking methods. Future trends emphasize integration of AI-driven analytics for precise milk yield prediction and enhanced herd management, promoting sustainable dairy farming. The shift towards AMS supports environmental sustainability by optimizing resource use and minimizing carbon footprints.

Automatic milking system vs Traditional milking for Cow milking Infographic

petrevi.com

petrevi.com