Hand milking allows for gentle extraction and personal observation of the cow's health, promoting a calming environment that can improve milk quality. Machine milking offers efficiency and consistency, enabling faster processing of large herds with reduced labor intensity. Choosing the optimal method depends on herd size, farm resources, and desired milk output quality.

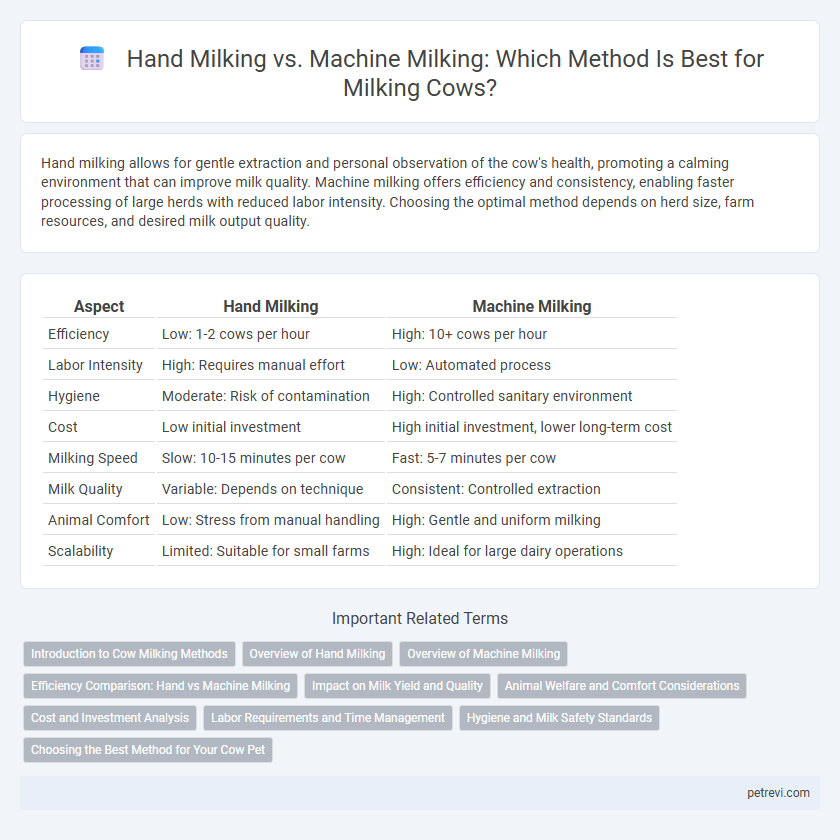

Table of Comparison

| Aspect | Hand Milking | Machine Milking |

|---|---|---|

| Efficiency | Low: 1-2 cows per hour | High: 10+ cows per hour |

| Labor Intensity | High: Requires manual effort | Low: Automated process |

| Hygiene | Moderate: Risk of contamination | High: Controlled sanitary environment |

| Cost | Low initial investment | High initial investment, lower long-term cost |

| Milking Speed | Slow: 10-15 minutes per cow | Fast: 5-7 minutes per cow |

| Milk Quality | Variable: Depends on technique | Consistent: Controlled extraction |

| Animal Comfort | Low: Stress from manual handling | High: Gentle and uniform milking |

| Scalability | Limited: Suitable for small farms | High: Ideal for large dairy operations |

Introduction to Cow Milking Methods

Hand milking, a traditional method, involves manually extracting milk from cows using fingers and hands, offering control over milk flow and minimal equipment costs. Machine milking employs automated milking machines that increase efficiency, reduce labor, and maintain consistent milk quality by using vacuum and pulsation technology. Both methods are widely used in dairy farming, with choice depending on farm size, labor availability, and production goals.

Overview of Hand Milking

Hand milking involves manually extracting milk from a cow's udder using hands, providing a gentle and natural approach often preferred in small-scale or traditional farming. This method allows farmers to closely monitor cow health and udder condition, reducing the risk of injury or infection. Hand milking typically produces lower milk volumes compared to machine milking but supports sustainable practices and deeper human-animal interaction.

Overview of Machine Milking

Machine milking employs automated systems like milking machines equipped with vacuum pumps and pulsators to efficiently extract milk from cows. This technology enhances milking speed, improves hygiene by minimizing direct contact, and supports consistent milk yield, making it ideal for large-scale dairy farms. Integration with data monitoring systems allows real-time tracking of milk production and cow health, optimizing overall farm management.

Efficiency Comparison: Hand vs Machine Milking

Machine milking significantly outperforms hand milking in efficiency by extracting milk faster and with consistent pressure, reducing the time per milking session from up to 30 minutes by hand to approximately 6-8 minutes by machine. Modern milking machines enhance milk yield through automated pulsation and vacuum systems that maintain udder health and minimize contamination risks. Hand milking, while gentler and cost-effective in small-scale operations, lacks the consistency and scalability needed for large dairy farms aiming to optimize productivity and labor costs.

Impact on Milk Yield and Quality

Hand milking often results in lower milk yield compared to machine milking due to less consistent stimulation and incomplete udder emptying. Machine milking enhances milk flow and volume while maintaining consistent milking intervals, which can improve overall milk quality by reducing bacterial contamination. However, improper machine settings or maintenance may cause teat damage, negatively affecting milk quality and udder health.

Animal Welfare and Comfort Considerations

Hand milking offers gentle stimulation, reducing stress and promoting cow comfort by mimicking natural calf sucking behavior, which can enhance oxytocin release and milk letdown. Machine milking, while faster and more efficient, can cause teat irritation or injury if not properly maintained or used, potentially compromising animal welfare. Proper equipment calibration and hygienic practices are essential in machine milking to minimize discomfort and prevent mastitis, ensuring optimal health and productivity in dairy cows.

Cost and Investment Analysis

Hand milking requires minimal initial investment, making it cost-effective for small-scale farmers, but it is labor-intensive and less efficient compared to machine milking. Machine milking demands a higher upfront cost for equipment purchase and maintenance, yet it significantly boosts milk yield and reduces labor expenses over time. Investing in automated milking machines can lead to long-term savings and increased productivity, especially in larger dairy operations.

Labor Requirements and Time Management

Hand milking a cow demands significant manual labor and time, typically requiring skill and patience to ensure efficient milk extraction. Machine milking drastically reduces labor intensity and shortens milking sessions, allowing farmers to manage larger herds with improved time efficiency. Automated milking systems also help optimize daily schedules by streamlining the milking process, increasing overall productivity on dairy farms.

Hygiene and Milk Safety Standards

Hand milking allows more direct control over hygiene by ensuring thorough cleaning of teats and milking equipment, reducing contamination risk. Machine milking, when properly maintained and sanitized, enhances milk safety by minimizing human contact and allowing consistent cleaning protocols. Both methods require strict adherence to hygiene standards to prevent bacterial growth and ensure high-quality milk production.

Choosing the Best Method for Your Cow Pet

Hand milking allows for gentle handling and closer cow-pet bonding, reducing stress and ensuring milk quality. Machine milking offers efficiency, consistency, and higher output, ideal for larger herds but requires proper maintenance to prevent udder infections. Evaluating cow temperament, herd size, and available resources helps determine the best milking method tailored to your cow pet's health and productivity.

Hand Milking vs Machine Milking for Cow Milking Infographic

petrevi.com

petrevi.com