Continuous flow systems in pig production allow animals of different ages to share facilities, increasing the risk of disease transmission and compromising biosecurity. All-in all-out systems improve herd health by moving groups of pigs together through production stages, enabling thorough cleaning and disinfection between batches. Implementing all-in all-out practices enhances productivity and reduces mortality compared to continuous flow methods.

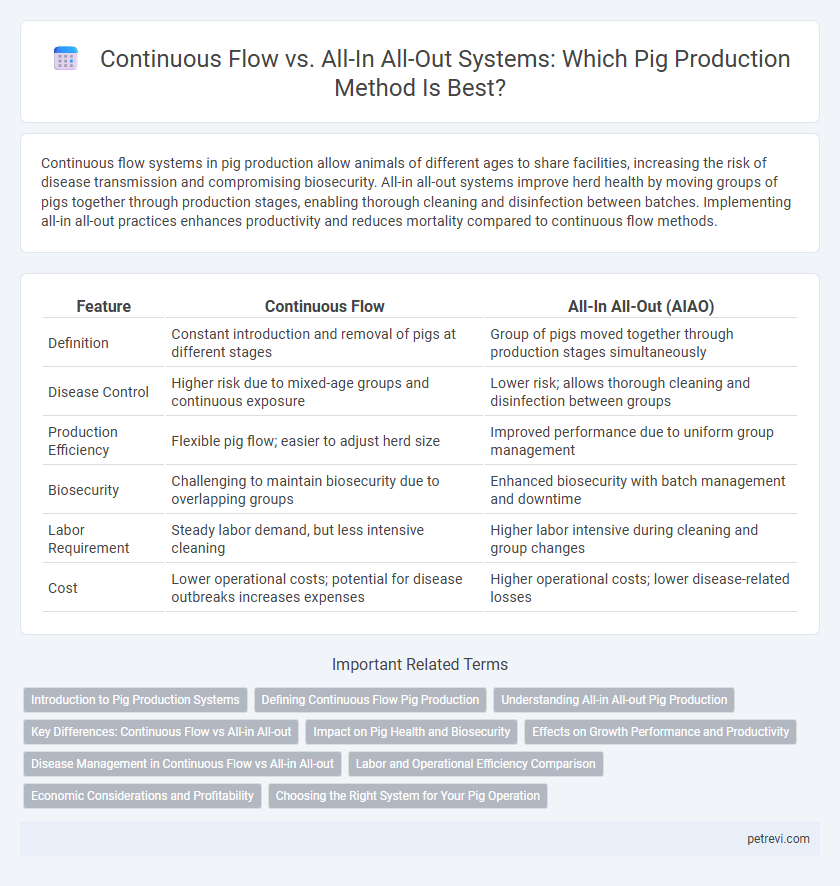

Table of Comparison

| Feature | Continuous Flow | All-In All-Out (AIAO) |

|---|---|---|

| Definition | Constant introduction and removal of pigs at different stages | Group of pigs moved together through production stages simultaneously |

| Disease Control | Higher risk due to mixed-age groups and continuous exposure | Lower risk; allows thorough cleaning and disinfection between groups |

| Production Efficiency | Flexible pig flow; easier to adjust herd size | Improved performance due to uniform group management |

| Biosecurity | Challenging to maintain biosecurity due to overlapping groups | Enhanced biosecurity with batch management and downtime |

| Labor Requirement | Steady labor demand, but less intensive cleaning | Higher labor intensive during cleaning and group changes |

| Cost | Lower operational costs; potential for disease outbreaks increases expenses | Higher operational costs; lower disease-related losses |

Introduction to Pig Production Systems

Continuous flow pig production systems allow pigs of different ages to be housed together, promoting flexible space utilization but increasing disease transmission risks. All-in all-out systems improve biosecurity by moving groups of pigs through production stages simultaneously, enabling thorough cleaning between batches and reducing pathogen spread. Efficient management of production stages in pig farming hinges on selecting the appropriate system to balance health control and operational capacity.

Defining Continuous Flow Pig Production

Continuous flow pig production involves the ongoing introduction and movement of pigs through various stages of production without complete depopulation of facilities between batches. This system contrasts with all-in all-out production, which requires entire groups of pigs to enter and leave facilities together to minimize disease transmission. Continuous flow can increase the risk of pathogen persistence and complicate biosecurity but allows for more flexible scheduling and facility utilization.

Understanding All-in All-out Pig Production

All-in All-out pig production system involves moving groups of pigs through production stages simultaneously, minimizing disease transmission by allowing thorough cleaning between batches. Continuous flow systems mix pigs of different ages and stages, increasing the risk of pathogen spread and reducing biosecurity effectiveness. Employing All-in All-out enhances herd health, improves growth rates, and increases overall productivity by disrupting disease cycles.

Key Differences: Continuous Flow vs All-in All-out

Continuous flow pig production systems allow pigs of different ages to occupy the same facility simultaneously, which can increase the risk of disease transmission and complicate biosecurity measures. In contrast, all-in all-out systems move groups of pigs through production phases as a single batch, facilitating thorough cleaning and disinfection between groups and reducing pathogen spread. This key difference emphasizes all-in all-out as more effective for disease control, while continuous flow may offer operational flexibility but potentially higher health risks.

Impact on Pig Health and Biosecurity

Continuous flow systems increase the risk of disease transmission among pigs due to overlapping age groups and constant animal movement, leading to compromised biosecurity and higher incidence of infections. All-in all-out systems enhance pig health by segregating groups by age and allowing thorough cleaning and disinfection between batches, significantly reducing pathogen buildup and improving overall herd immunity. Implementing all-in all-out practices optimizes biosecurity protocols and minimizes disease outbreak risks, thereby supporting sustainable pig production.

Effects on Growth Performance and Productivity

Continuous flow pig production systems often lead to increased disease transmission, negatively impacting growth performance and overall productivity. All-in all-out systems improve biosecurity by reducing pathogen exposure, resulting in better weight gain and feed efficiency. Implementing all-in all-out practices enhances pig health outcomes and optimizes production cycle efficiency.

Disease Management in Continuous Flow vs All-in All-out

Continuous flow pig production systems increase the risk of disease transmission due to the constant presence of pigs at varying growth stages, which creates persistent pathogen reservoirs. All-in all-out systems enhance disease management by allowing thorough cleaning and disinfection between groups, significantly reducing pathogen load and interruption of disease cycles. This controlled environment decreases morbidity and mortality rates, leading to improved herd health and productivity.

Labor and Operational Efficiency Comparison

Continuous flow pig production requires constant labor input for daily monitoring and cleaning, which can increase operational costs due to its ongoing management needs. The all-in all-out system enhances labor efficiency by synchronizing pig groups, allowing for thorough cleaning and disinfection between batches, reducing disease risk and downtime. Operational efficiency improves in all-in all-out systems by minimizing cross-contamination and optimizing resource use, leading to better growth performance and lower labor intensity per production cycle.

Economic Considerations and Profitability

Continuous flow pig production systems often incur higher disease management costs due to increased pathogen transmission risk, affecting overall profitability. All-in all-out systems, although requiring strict scheduling and downtime between batches, enhance biosecurity and reduce veterinary expenses, leading to improved economic efficiency. The choice between systems hinges on balancing labor input, feed efficiency, and market timing to maximize returns on investment in pig production.

Choosing the Right System for Your Pig Operation

Continuous flow systems in pig production allow steady animal movement but increase the risk of disease transmission and require stringent biosecurity measures. All-in all-out systems promote herd health by moving groups simultaneously, enabling thorough cleaning and reducing infection cycles. Selecting the appropriate system depends on operation size, management capabilities, and disease control priorities to optimize productivity and animal welfare.

Continuous flow vs All-in all-out for Pig production system Infographic

petrevi.com

petrevi.com