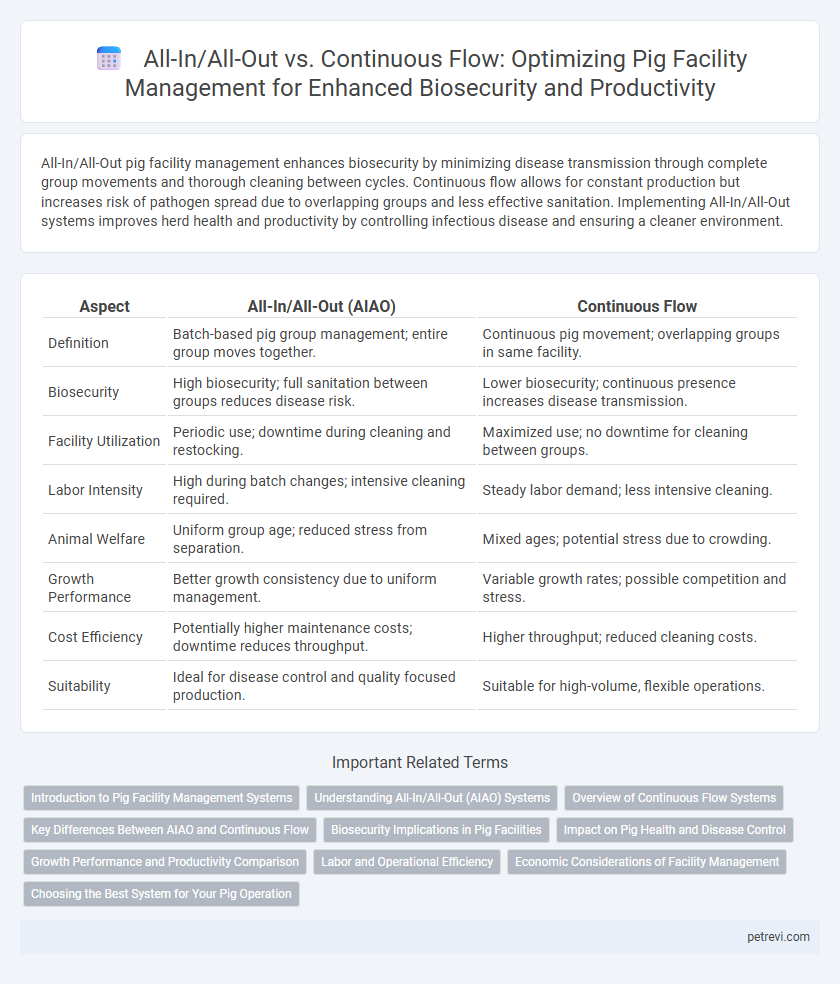

All-In/All-Out pig facility management enhances biosecurity by minimizing disease transmission through complete group movements and thorough cleaning between cycles. Continuous flow allows for constant production but increases risk of pathogen spread due to overlapping groups and less effective sanitation. Implementing All-In/All-Out systems improves herd health and productivity by controlling infectious disease and ensuring a cleaner environment.

Table of Comparison

| Aspect | All-In/All-Out (AIAO) | Continuous Flow |

|---|---|---|

| Definition | Batch-based pig group management; entire group moves together. | Continuous pig movement; overlapping groups in same facility. |

| Biosecurity | High biosecurity; full sanitation between groups reduces disease risk. | Lower biosecurity; continuous presence increases disease transmission. |

| Facility Utilization | Periodic use; downtime during cleaning and restocking. | Maximized use; no downtime for cleaning between groups. |

| Labor Intensity | High during batch changes; intensive cleaning required. | Steady labor demand; less intensive cleaning. |

| Animal Welfare | Uniform group age; reduced stress from separation. | Mixed ages; potential stress due to crowding. |

| Growth Performance | Better growth consistency due to uniform management. | Variable growth rates; possible competition and stress. |

| Cost Efficiency | Potentially higher maintenance costs; downtime reduces throughput. | Higher throughput; reduced cleaning costs. |

| Suitability | Ideal for disease control and quality focused production. | Suitable for high-volume, flexible operations. |

Introduction to Pig Facility Management Systems

Pig facility management systems implement either All-In/All-Out or Continuous Flow strategies to optimize health and productivity within swine operations. All-In/All-Out batching enhances biosecurity by moving groups of pigs simultaneously through production stages, minimizing disease transmission and improving sanitation protocols. Continuous Flow systems allow for ongoing pig movement, increasing operational flexibility but requiring stringent health monitoring to mitigate risks of pathogen spread.

Understanding All-In/All-Out (AIAO) Systems

All-In/All-Out (AIAO) systems in pig facility management enhance biosecurity by grouping pigs of the same age and moving them through production stages simultaneously, minimizing disease transmission. This method allows for complete cleaning and disinfection between groups, reducing pathogen buildup in the environment. Implementing AIAO strategies leads to improved herd health, better growth performance, and optimized facility utilization compared to continuous flow systems.

Overview of Continuous Flow Systems

Continuous Flow Systems in pig facility management enable unrestricted movement of pigs between groups and stages, differing from the batch-based All-In/All-Out approach. This method supports ongoing production processes but increases the risk of disease transmission due to mixed-age groups and shared environments. Effective biosecurity and health monitoring are crucial to mitigate challenges associated with continuous flow systems.

Key Differences Between AIAO and Continuous Flow

The All-In/All-Out (AIAO) system segregates pig groups by age, minimizing disease transmission through complete cleaning and disinfection between groups, while continuous flow allows multiple age groups to coexist, increasing infection risk. AIAO enhances biosecurity and production efficiency by reducing pathogen buildup, whereas continuous flow may lead to slower growth rates and higher mortality due to cross-contamination. Facility management using AIAO requires strict scheduling and downtime, contrasting with the flexible but riskier operational approach of continuous flow.

Biosecurity Implications in Pig Facilities

All-In/All-Out (AIAO) pig facility management significantly enhances biosecurity by minimizing pathogen transmission between groups, as entire cohorts are moved simultaneously and facilities are thoroughly cleaned before the next group's arrival. Continuous Flow systems increase biosecurity risks due to the constant introduction of new pigs at various stages, creating overlapping groups that facilitate disease spread. Implementing AIAO coupled with disinfection protocols reduces cross-contamination, improves herd health, and optimizes disease control in pig farming operations.

Impact on Pig Health and Disease Control

All-In/All-Out (AIAO) pig facility management significantly reduces the risk of disease transmission by allowing thorough cleaning and disinfection between groups, promoting better pig health and biosecurity. Continuous Flow systems increase the likelihood of pathogen persistence and cross-contamination due to overlapping age groups, resulting in higher stress and susceptibility to diseases like Porcine Reproductive and Respiratory Syndrome (PRRS) and Swine Influenza Virus (SIV). Implementing AIAO practices improves overall herd immunity, reduces antimicrobial usage, and enhances growth performance by minimizing disease outbreaks.

Growth Performance and Productivity Comparison

All-In/All-Out (AIAO) management significantly improves pig growth performance by minimizing disease transmission and optimizing environmental control, leading to uniform weight gain and better feed conversion ratios. Continuous Flow systems often result in higher disease prevalence and slower growth due to overlapping age groups and inconsistent hygiene practices. Studies show that AIAO practices enhance overall productivity by reducing mortality rates and veterinary costs, ultimately increasing profitability in pig facilities.

Labor and Operational Efficiency

All-In/All-Out (AIAO) pig facility management enhances labor efficiency by allowing synchronized cleaning and restocking, reducing downtime and minimizing disease transmission. Continuous Flow systems demand constant labor monitoring and intervention, leading to increased operational complexities and higher labor costs. Optimizing pig health and productivity is more feasible with AIAO, as dedicated operational cycles streamline biosecurity and resource allocation.

Economic Considerations of Facility Management

All-In/All-Out (AIAO) pig facility management optimizes economic efficiency by minimizing disease transmission, reducing medication costs, and enhancing growth performance through synchronized batch processing. Continuous Flow systems often increase operational expenses due to higher disease prevalence, extended recovery times, and inconsistent feeding regimens, which negatively impact feed conversion ratios and mortality rates. Economic analysis shows AIAO improves return on investment by maximizing pig health and uniformity, leading to better market weights and reduced veterinary interventions.

Choosing the Best System for Your Pig Operation

All-In/All-Out (AIAO) systems enhance biosecurity and reduce disease transmission by moving groups of pigs simultaneously, minimizing pathogen exposure and improving overall herd health. Continuous Flow systems, while offering flexibility in production, increase the risk of disease spread due to mixing pigs of different ages and statuses, which can lead to inconsistent growth rates and higher mortality. Selecting the best system depends on your operation's size, management capacity, and disease control priorities, with AIAO generally recommended for maximizing health and productivity in commercial pig facilities.

All-In/All-Out vs Continuous Flow for Pig Facility Management Infographic

petrevi.com

petrevi.com