Manual manure removal in pig waste management requires significant labor and time, often resulting in inconsistent cleanliness and increased risk of environmental contamination. Mechanical scrapers offer a more efficient and reliable solution by automating waste removal, improving hygiene while reducing labor costs. Choosing the appropriate method depends on farm size, budget, and desired sanitation standards.

Table of Comparison

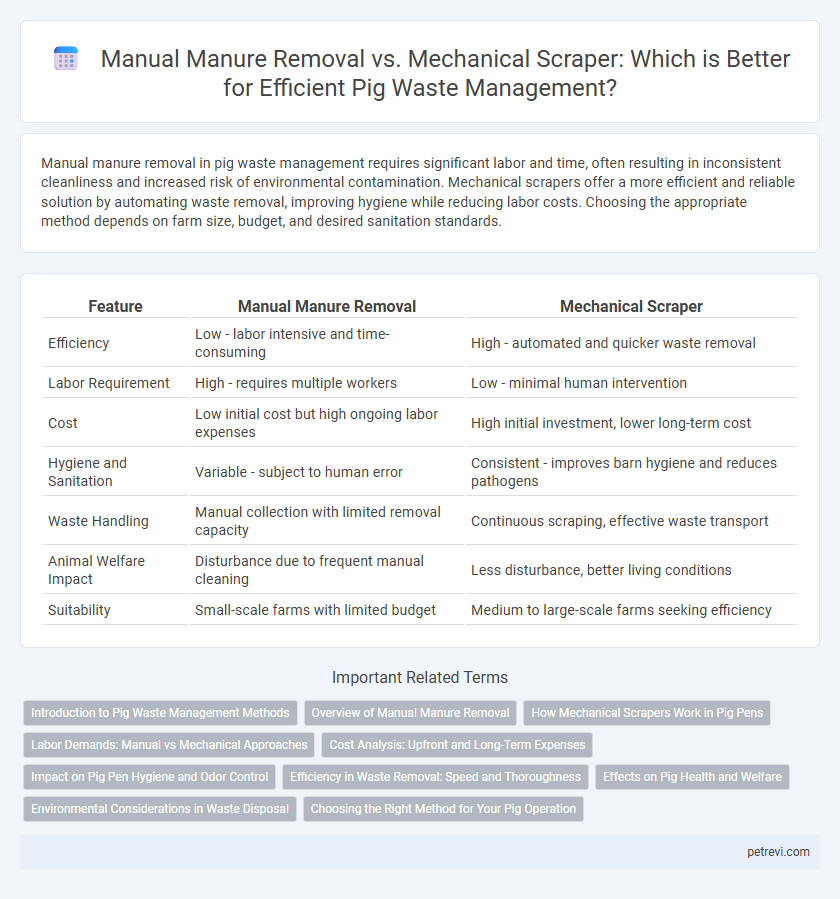

| Feature | Manual Manure Removal | Mechanical Scraper |

|---|---|---|

| Efficiency | Low - labor intensive and time-consuming | High - automated and quicker waste removal |

| Labor Requirement | High - requires multiple workers | Low - minimal human intervention |

| Cost | Low initial cost but high ongoing labor expenses | High initial investment, lower long-term cost |

| Hygiene and Sanitation | Variable - subject to human error | Consistent - improves barn hygiene and reduces pathogens |

| Waste Handling | Manual collection with limited removal capacity | Continuous scraping, effective waste transport |

| Animal Welfare Impact | Disturbance due to frequent manual cleaning | Less disturbance, better living conditions |

| Suitability | Small-scale farms with limited budget | Medium to large-scale farms seeking efficiency |

Introduction to Pig Waste Management Methods

Manual manure removal in pig waste management involves labor-intensive processes where workers physically collect and dispose of pig waste, offering control but limited efficiency in large-scale operations. Mechanical scrapers automate waste removal by using machinery to scrape manure from pig housing, significantly improving sanitation and reducing labor costs in intensive pig farming. Effective pig waste management methods prioritize environmental sustainability and operational efficiency to mitigate odor, disease risks, and pollution.

Overview of Manual Manure Removal

Manual manure removal in pig waste management involves labor-intensive processes where workers use tools such as shovels and wheelbarrows to collect and dispose of manure. This method offers precise control in small-scale pig farms and reduces initial equipment costs but is time-consuming and laborious. Manual removal also poses higher risks of exposure to pathogens and requires strict hygiene measures to protect workers' health.

How Mechanical Scrapers Work in Pig Pens

Mechanical scrapers in pig pens operate by using motorized systems to automatically push or pull manure along slatted floors into collection pits, reducing labor and improving hygiene. These scrapers are typically programmed to run at set intervals, ensuring consistent waste removal and minimizing ammonia buildup in the barn environment. Compared to manual manure removal, mechanical scrapers enhance efficiency, maintain cleaner pens, and support better air quality for pig health and productivity.

Labor Demands: Manual vs Mechanical Approaches

Manual manure removal in pig waste management demands intensive labor, requiring workers to physically shovel and transport waste, which increases time and fatigue. Mechanical scrapers significantly reduce labor demands by automating waste collection, enabling consistent cleaning with fewer workers and less physical strain. Implementing mechanical scrapers enhances operational efficiency and can lower labor costs in large-scale pig farming systems.

Cost Analysis: Upfront and Long-Term Expenses

Manual manure removal for pig waste management involves lower upfront costs due to minimal equipment investment but incurs higher long-term labor expenses and potential inefficiencies. Mechanical scrapers require significant initial capital for purchase and installation but reduce ongoing labor costs, improve waste removal efficiency, and can lower overall maintenance expenses over time. Evaluating total cost of ownership highlights mechanical scrapers as a cost-effective solution when scaled operations and labor rates are considered.

Impact on Pig Pen Hygiene and Odor Control

Manual manure removal requires frequent labor and often leaves residues that can contribute to unpleasant odors and compromised pig pen hygiene. Mechanical scrapers efficiently remove waste with consistent thoroughness, significantly reducing odor levels and promoting a cleaner environment for pigs. Automated systems minimize ammonia buildup and bacterial growth, enhancing overall animal health and welfare.

Efficiency in Waste Removal: Speed and Thoroughness

Mechanical scrapers outperform manual manure removal in pig waste management by significantly increasing speed and thoroughness, effectively handling large volumes of waste in less time. Scrapers maintain cleaner pens through consistent and rapid waste removal, reducing ammonia levels and improving animal health. Manual methods often result in uneven cleaning and slower removal, leading to suboptimal hygiene conditions in pig farming operations.

Effects on Pig Health and Welfare

Manual manure removal allows for more frequent and targeted cleaning, reducing ammonia levels and minimizing respiratory issues in pigs. Mechanical scrapers provide consistent waste removal, which helps maintain stable barn hygiene but may cause stress or injury if pigs are startled by moving machinery. Properly managed mechanical systems can improve overall welfare by decreasing labor intensity and ensuring timely waste removal, promoting a healthier living environment.

Environmental Considerations in Waste Disposal

Manual manure removal in pig waste management typically results in less energy consumption and lower greenhouse gas emissions compared to mechanical scrapers, promoting a smaller carbon footprint. Mechanical scrapers, while efficient in large-scale operations, can contribute to increased noise pollution and energy use, potentially impacting surrounding ecosystems. Effective waste disposal strategies must balance operational efficiency with minimizing environmental harm, including controlling nutrient runoff and preserving soil and water quality.

Choosing the Right Method for Your Pig Operation

Choosing the right manure removal method for pig operations depends on herd size, facility design, and labor availability. Manual removal offers low equipment costs and precise waste handling but demands significant labor and time, making it ideal for smaller farms. Mechanical scrapers enhance efficiency and sanitation in larger-scale pig barns by automating waste removal, reducing labor inputs, and minimizing environmental impact through more consistent manure management.

Manual manure removal vs Mechanical scraper for Pig waste management Infographic

petrevi.com

petrevi.com