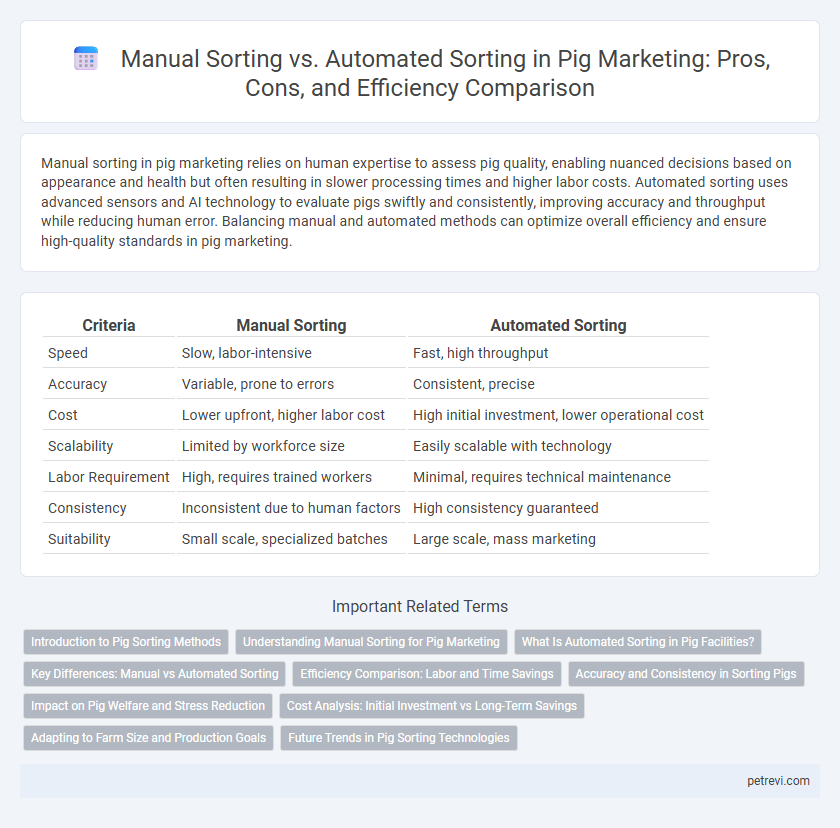

Manual sorting in pig marketing relies on human expertise to assess pig quality, enabling nuanced decisions based on appearance and health but often resulting in slower processing times and higher labor costs. Automated sorting uses advanced sensors and AI technology to evaluate pigs swiftly and consistently, improving accuracy and throughput while reducing human error. Balancing manual and automated methods can optimize overall efficiency and ensure high-quality standards in pig marketing.

Table of Comparison

| Criteria | Manual Sorting | Automated Sorting |

|---|---|---|

| Speed | Slow, labor-intensive | Fast, high throughput |

| Accuracy | Variable, prone to errors | Consistent, precise |

| Cost | Lower upfront, higher labor cost | High initial investment, lower operational cost |

| Scalability | Limited by workforce size | Easily scalable with technology |

| Labor Requirement | High, requires trained workers | Minimal, requires technical maintenance |

| Consistency | Inconsistent due to human factors | High consistency guaranteed |

| Suitability | Small scale, specialized batches | Large scale, mass marketing |

Introduction to Pig Sorting Methods

Manual pig sorting relies on human labor to identify and separate pigs based on size, weight, and health conditions, offering flexibility but limited scalability for large farms. Automated sorting uses sensor technology, such as RFID tags and weight scales, to efficiently classify pigs, improving accuracy and throughput in commercial pig marketing. Choosing between manual and automated sorting impacts operational efficiency, animal welfare, and overall profitability in pig production systems.

Understanding Manual Sorting for Pig Marketing

Manual sorting in pig marketing involves visually inspecting pigs to assess qualities such as size, weight, and health, enabling farmers to categorize animals based on specific market demands. This hands-on method facilitates immediate decision-making and tailored sorting but can be time-consuming and prone to human error. Emphasizing manual sorting helps maintain detailed, personalized evaluations crucial for niche markets requiring specific pig attributes.

What Is Automated Sorting in Pig Facilities?

Automated sorting in pig facilities utilizes advanced technologies such as RFID tags, sensors, and machine learning algorithms to efficiently classify pigs by weight, size, and health status. This system minimizes human labor, reduces sorting errors, and enhances throughput by quickly directing pigs to appropriate marketing categories. The data collected through automated sorting also enables precise market targeting and improves overall herd management strategies.

Key Differences: Manual vs Automated Sorting

Manual sorting of pigs relies on human judgment to classify animals based on physical traits, which may lead to inconsistency and slower processing speeds. Automated sorting employs advanced technologies like RFID tagging, machine vision, and AI algorithms to ensure precise, uniform categorization and increased throughput. Key differences include accuracy, speed, labor costs, and scalability, with automated systems optimizing pig marketing efficiency through data-driven decision-making.

Efficiency Comparison: Labor and Time Savings

Automated sorting in pig marketing significantly reduces labor costs by minimizing the need for manual handling and repetitive tasks, leading to faster processing times. Manual sorting requires extensive human intervention, which increases labor hours and introduces variability in sorting accuracy. The efficiency of automated systems improves throughput and consistency, enabling higher productivity and quicker turnaround in pig marketing operations.

Accuracy and Consistency in Sorting Pigs

Manual sorting of pigs relies heavily on human judgment, which can lead to variability in accuracy and consistency due to subjective assessments and fatigue. Automated sorting systems utilize advanced sensors and machine learning algorithms to achieve precise, repeatable classifications based on size, weight, and health indicators, enhancing overall sorting reliability. Consistent sorting improves market value by ensuring uniformity in pig batches, reducing handling errors, and optimizing supply chain efficiency.

Impact on Pig Welfare and Stress Reduction

Manual sorting in pig marketing allows for gentle handling and close observation of individual animals, which significantly reduces stress and promotes better welfare. Automated sorting systems increase efficiency but may cause higher stress levels due to faster movement and limited human interaction, potentially impacting pig well-being. Optimizing sorting methods by integrating gentle handling protocols within automated systems can enhance pig welfare and reduce stress during marketing processes.

Cost Analysis: Initial Investment vs Long-Term Savings

Manual sorting of pigs involves lower initial investment costs but incurs higher ongoing labor expenses and reduced processing speed, impacting overall profitability. Automated sorting systems require significant upfront capital for equipment and technology but deliver long-term savings through increased efficiency, consistent quality control, and reduced labor costs. Over time, automated sorting enhances cost-effectiveness and scalability in pig marketing operations by optimizing resource allocation and reducing operational bottlenecks.

Adapting to Farm Size and Production Goals

Manual sorting in pig marketing allows precise selection tailored to small-scale farms with varied production goals, offering flexibility in handling unique animal characteristics. Automated sorting systems optimize efficiency and consistency, making them ideal for large-scale operations focused on high throughput and standardized quality. Adapting sorting methods to farm size and production aims enhances marketability and operational efficiency in pig production.

Future Trends in Pig Sorting Technologies

Manual sorting in pig marketing remains labor-intensive and prone to human error, limiting efficiency and scalability. Automated sorting technology leverages sensors, machine learning, and real-time data analytics to accurately classify pigs based on weight, health, and breed traits. Future trends emphasize integration of AI-driven systems, IoT-enabled devices, and blockchain for traceability, promising enhanced precision, speed, and transparency in pig sorting processes.

Manual sorting vs Automated sorting for Pig marketing Infographic

petrevi.com

petrevi.com