Manual shearing offers precise control and is less stressful for sheep, making it ideal for small flocks and delicate wool types. Electric shearing provides faster, more efficient wool removal, increasing productivity in large-scale operations while requiring regular maintenance and power supply. Choosing between manual and electric methods depends on flock size, wool quality, and available resources.

Table of Comparison

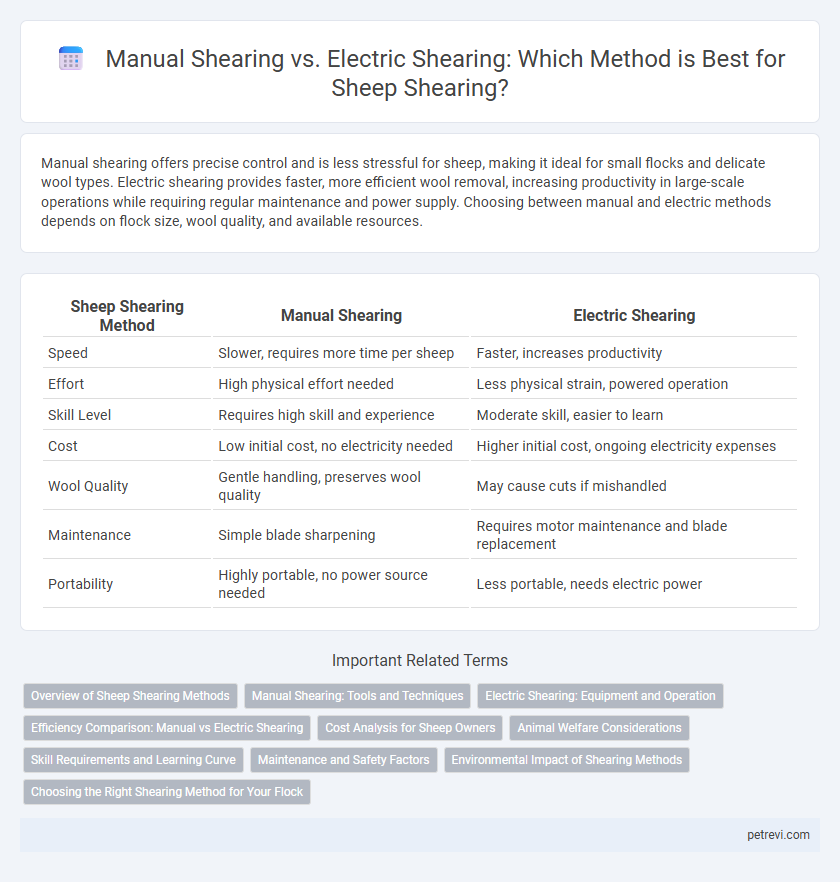

| Sheep Shearing Method | Manual Shearing | Electric Shearing |

|---|---|---|

| Speed | Slower, requires more time per sheep | Faster, increases productivity |

| Effort | High physical effort needed | Less physical strain, powered operation |

| Skill Level | Requires high skill and experience | Moderate skill, easier to learn |

| Cost | Low initial cost, no electricity needed | Higher initial cost, ongoing electricity expenses |

| Wool Quality | Gentle handling, preserves wool quality | May cause cuts if mishandled |

| Maintenance | Simple blade sharpening | Requires motor maintenance and blade replacement |

| Portability | Highly portable, no power source needed | Less portable, needs electric power |

Overview of Sheep Shearing Methods

Manual shearing of sheep involves traditional hand tools such as blades, relying on skilled shearers to manually remove wool with precision and minimal skin damage. Electric shearing uses powered clippers to efficiently shear large flocks, significantly reducing time and labor while maintaining wool quality when operated correctly. Both methods require proper technique to ensure animal welfare and wool yield, with electric shearing favored for commercial operations and manual shearing preferred in skill-focused or small-scale settings.

Manual Shearing: Tools and Techniques

Manual shearing of sheep relies primarily on traditional hand shears, which are manually operated scissors designed specifically for efficient wool removal. Expert shearers use precise techniques that involve steady hand movements and careful positioning to minimize animal stress and maximize fleece quality. This method requires considerable skill and physical endurance but allows for greater control over the shearing process in areas without access to electricity.

Electric Shearing: Equipment and Operation

Electric shearing for sheep employs high-speed, motorized clippers designed to efficiently remove wool with precision and reduced physical effort. The essential equipment includes a reliable electric shearer with sharp, interchangeable blades and an ergonomic handle to ensure comfort during extended use. Proper operation involves maintaining consistent blade speed and angle to prevent skin injury, while regular lubrication and blade sharpening optimize performance and durability.

Efficiency Comparison: Manual vs Electric Shearing

Electric shearing significantly increases efficiency by reducing the time required to shear a sheep, often cutting the process to under five minutes compared to the 15-20 minutes typical of manual shearing. The motorized electric clippers maintain consistent blade speed, minimizing interruptions and ensuring a smoother, more uniform cut. Manual shearing demands greater physical effort and skill, resulting in slower processing and potential variability in fleece quality.

Cost Analysis for Sheep Owners

Manual shearing requires minimal upfront investment, relying primarily on the shearer's skill and simple hand tools, making it cost-effective for small-scale sheep owners. In contrast, electric shearing involves higher initial costs due to the purchase of electric clippers and ongoing expenses for maintenance and electricity consumption. Over time, electric shearing can increase productivity and reduce labor hours, potentially offsetting higher startup costs for larger flocks.

Animal Welfare Considerations

Manual shearing minimizes stress by allowing slower, controlled movements that reduce the risk of cuts and injuries to sheep. Electric shearing, while faster and more efficient, requires skilled operators to prevent overheating and skin damage, ensuring animal comfort. Prioritizing animal welfare demands careful handling and regular equipment maintenance regardless of the shearing method used.

Skill Requirements and Learning Curve

Manual shearing demands high skill and precision, as it requires mastering traditional hand techniques to efficiently remove fleece without harming the sheep. The learning curve for manual shearing is steep, often taking months or years to develop the necessary hand-eye coordination and muscle memory. Electric shearing, while still requiring skill to control the machine and avoid cuts, typically has a shorter learning curve due to the mechanized process and ergonomic design.

Maintenance and Safety Factors

Manual shearing requires minimal equipment maintenance, primarily involving regular sharpening of blades and cleaning to prevent rust, making it low-cost and straightforward for small-scale farmers. Electric shearing necessitates consistent motor maintenance, blade lubrication, and electrical safety checks to prevent overheating and potential electrical hazards during operation. Safety risks differ as manual shearing reduces electrical injuries but demands physical strength and skill to avoid cuts, whereas electric shearing increases efficiency but requires caution to prevent electric shocks and equipment malfunctions.

Environmental Impact of Shearing Methods

Manual shearing produces minimal environmental impact as it requires no electricity and generates negligible noise pollution, making it highly sustainable for small-scale sheep farming. Electric shearing, while more efficient, relies on electrical power that may come from non-renewable sources, increasing its carbon footprint and contributing to greenhouse gas emissions. Choosing manual shearing supports eco-friendly practices by reducing energy consumption and limiting environmental disturbances in sheep shearing operations.

Choosing the Right Shearing Method for Your Flock

Manual shearing offers precision and control, making it ideal for small flocks or delicate breeds where stress minimization is crucial. Electric shearing enhances efficiency and speed, suitable for large-scale operations requiring rapid fleece removal with consistent quality. Selecting the appropriate method depends on flock size, sheep temperament, and available resources, ensuring optimal wool quality and animal welfare.

Manual Shearing vs Electric Shearing for Sheep Shearing Method Infographic

petrevi.com

petrevi.com