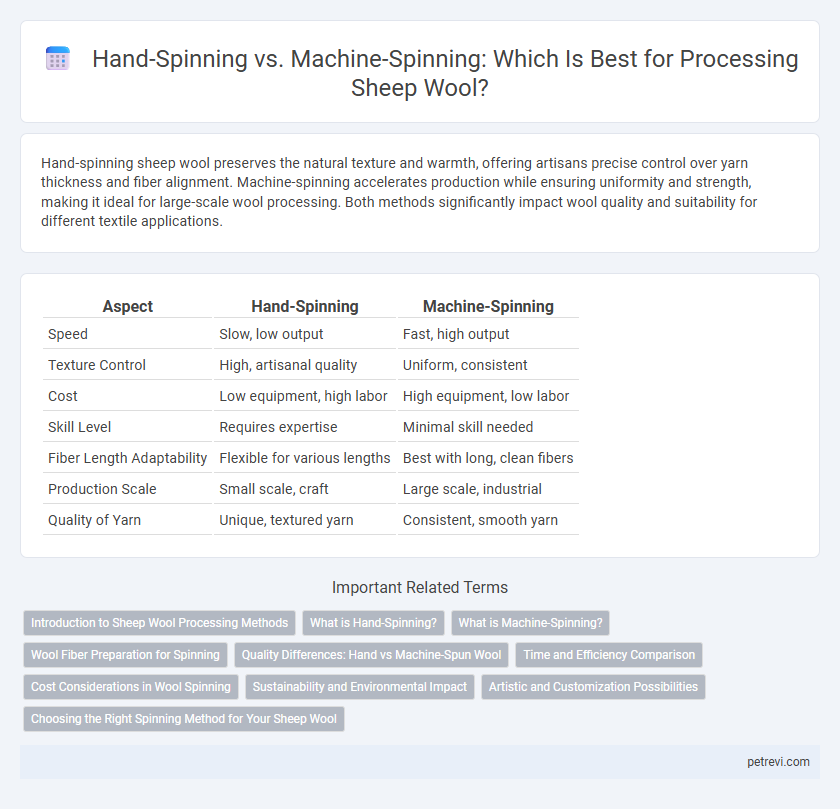

Hand-spinning sheep wool preserves the natural texture and warmth, offering artisans precise control over yarn thickness and fiber alignment. Machine-spinning accelerates production while ensuring uniformity and strength, making it ideal for large-scale wool processing. Both methods significantly impact wool quality and suitability for different textile applications.

Table of Comparison

| Aspect | Hand-Spinning | Machine-Spinning |

|---|---|---|

| Speed | Slow, low output | Fast, high output |

| Texture Control | High, artisanal quality | Uniform, consistent |

| Cost | Low equipment, high labor | High equipment, low labor |

| Skill Level | Requires expertise | Minimal skill needed |

| Fiber Length Adaptability | Flexible for various lengths | Best with long, clean fibers |

| Production Scale | Small scale, craft | Large scale, industrial |

| Quality of Yarn | Unique, textured yarn | Consistent, smooth yarn |

Introduction to Sheep Wool Processing Methods

Sheep wool processing methods include hand-spinning and machine-spinning, each offering distinct advantages for fiber quality and texture. Hand-spinning preserves the natural crimp and softness of wool fibers, resulting in unique, artisanal yarns ideal for fine textiles and craft projects. Machine-spinning, in contrast, enables large-scale production with consistent thread strength, making it suitable for industrial fabric manufacturing and mass-market wool products.

What is Hand-Spinning?

Hand-spinning is a traditional method of processing sheep wool that involves manually twisting fibers into yarn using tools like a spindle or spinning wheel. This technique allows for greater control over yarn thickness and texture, producing artisanal fibers prized for their unique qualities. Hand-spinning preserves the natural characteristics of sheep wool, making it a favored choice for craftspeople and small-scale wool producers.

What is Machine-Spinning?

Machine-spinning is an industrial process that uses automated equipment to twist and draw out sheep wool fibers into yarn at high speed and consistent quality. This method enables large-scale production with uniform thickness, reducing labor time compared to traditional hand-spinning. Efficiency and scalability make machine-spinning ideal for commercial wool processing, supplying textile manufacturers worldwide.

Wool Fiber Preparation for Spinning

Hand-spinning sheep wool requires meticulous fiber preparation, including carding and combing to align fibers and remove impurities, resulting in a more controlled and textured yarn. Machine-spinning processes utilize industrial carding machines and automated blending systems to efficiently prepare large volumes of wool fiber, ensuring uniformity and consistent fiber length for smooth spinning. Proper wool fiber preparation impacts yarn strength, elasticity, and overall quality in both hand-spinning and machine-spinning methods.

Quality Differences: Hand vs Machine-Spun Wool

Hand-spun sheep wool typically boasts superior fiber integrity and softness due to the careful, controlled drafting process that preserves individual fiber characteristics, resulting in a more textured and resilient yarn. Machine-spun wool, while consistent and efficient for large-scale production, often experiences fiber damage and reduced elasticity from high-speed mechanical tension, which can lead to a less durable and homogenized yarn quality. The distinction in fiber alignment and twist tension between hand and machine spinning directly influences the final wool product's strength, softness, and overall tactile appeal.

Time and Efficiency Comparison

Hand-spinning sheep wool typically processes small quantities at a slower rate, averaging 1 to 2 hours per ounce, allowing for greater control over fiber texture. Machine-spinning, using industrial equipment, can spin several pounds per hour, vastly increasing efficiency and consistent yarn quality. Time savings with machine-spinning enable large-scale wool production, though hand-spinning maintains artisanal craftsmanship valued in niche markets.

Cost Considerations in Wool Spinning

Hand-spinning sheep wool involves lower initial equipment costs but demands significant time investment and skilled labor, making it less cost-effective for large-scale production. Machine-spinning requires substantial upfront investment in machinery and maintenance but offers higher throughput and consistency, reducing per-unit costs in bulk processing. Evaluating these cost factors is crucial for wool producers aiming to balance quality, efficiency, and profitability in their spinning operations.

Sustainability and Environmental Impact

Hand-spinning sheep wool generates minimal carbon emissions and promotes sustainable fiber use by reducing reliance on electricity and fossil fuels. Machine-spinning increases production efficiency but consumes significant energy and contributes to environmental pollution through chemical processing and waste. Opting for hand-spinning supports eco-friendly practices and preserves traditional craftsmanship, aligning with sustainable wool production goals.

Artistic and Customization Possibilities

Hand-spinning sheep wool allows artisans to create unique textures and intricate patterns tailored to specific artistic visions, offering unmatched customization in fiber thickness and color blending. Machine-spinning provides consistent yarn quality and high production speed but lacks the nuanced control that fosters individual creativity and bespoke design elements. Artists favor hand-spinning for projects requiring personalized craftsmanship and experimental techniques, enhancing the wool's natural aesthetic appeal.

Choosing the Right Spinning Method for Your Sheep Wool

Hand-spinning sheep wool allows for greater control over fiber texture and quality, making it ideal for artisanal and small-batch projects that emphasize craftsmanship. Machine-spinning offers efficiency and consistency, suitable for large-scale production where uniform yarn strength and speed are priorities. Selecting the right spinning method depends on your wool type, desired yarn characteristics, and production scale to maximize the value of your sheep wool.

Hand-spinning vs Machine-spinning for Sheep Wool Processing Infographic

petrevi.com

petrevi.com